08 Feb 2016

Things to do this week

Figuring out the dimension of the cylinder (for stable model).

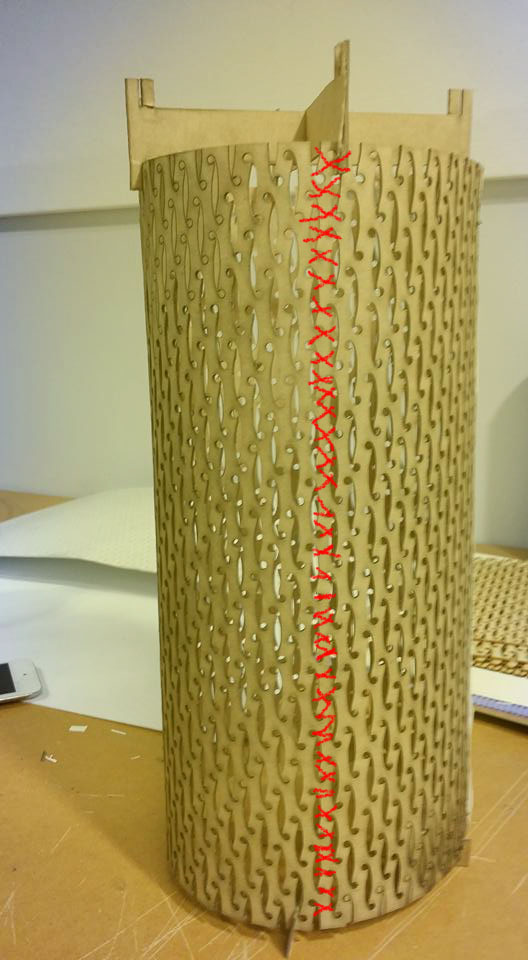

Trying to overlap both ends so we dont have to sew.

figuring out Arduino (programming).

Test prototype with bamboo (see if it behaves well and bend as we want to).

If it doesn`t change material to cardboard or work more on kerf bend so bamboo can bend more.

08 Feb 2016

just a quick google search has showed that using a 1:2 ratio for a cyclender is the most effecient size, however applying the golden ratio will give the best looking cyclender.

link to website

link to website

07 Feb 2016

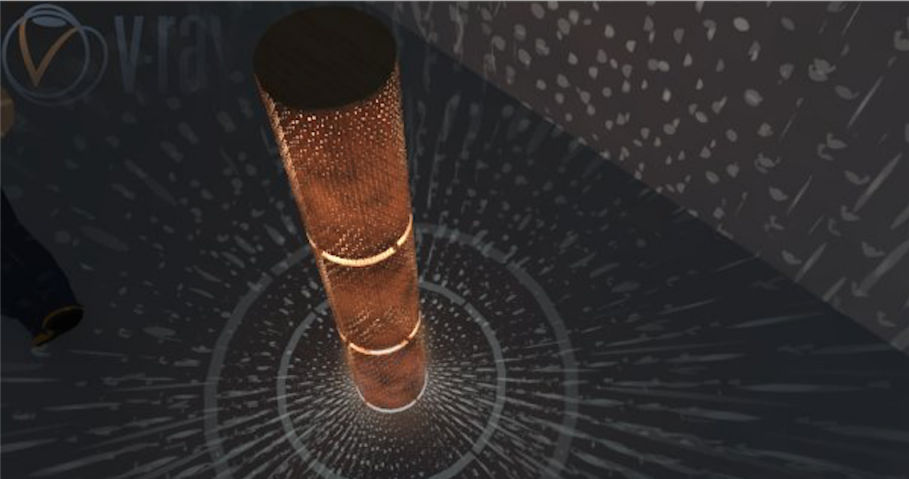

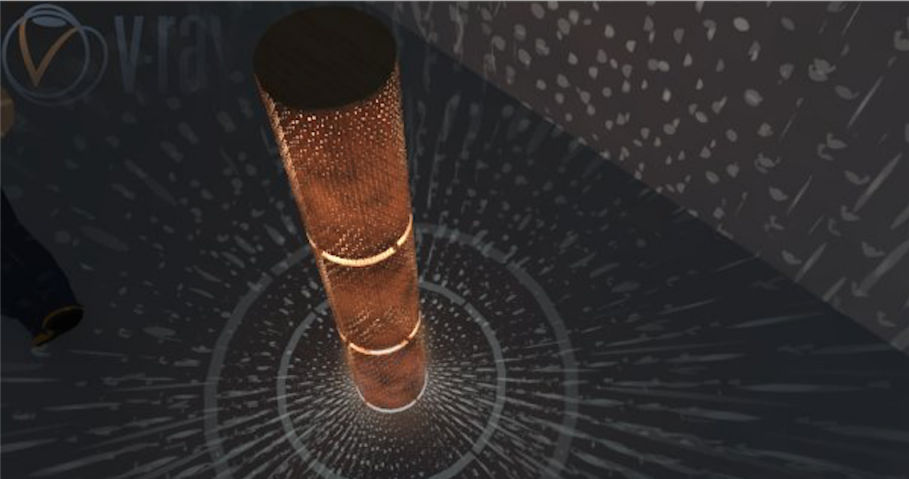

We’re interested in creating a customizable and sustainable motion sensor light. That also looks really nice.

For our main material we’re using a 3mm bamboo ply.

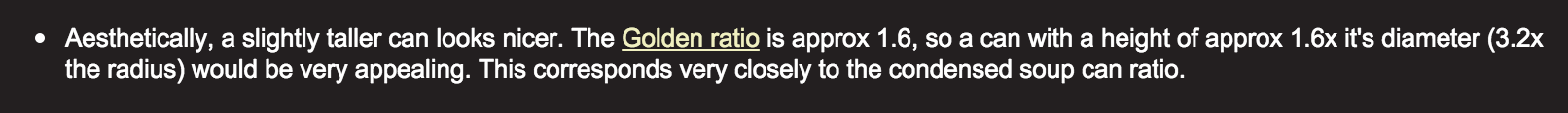

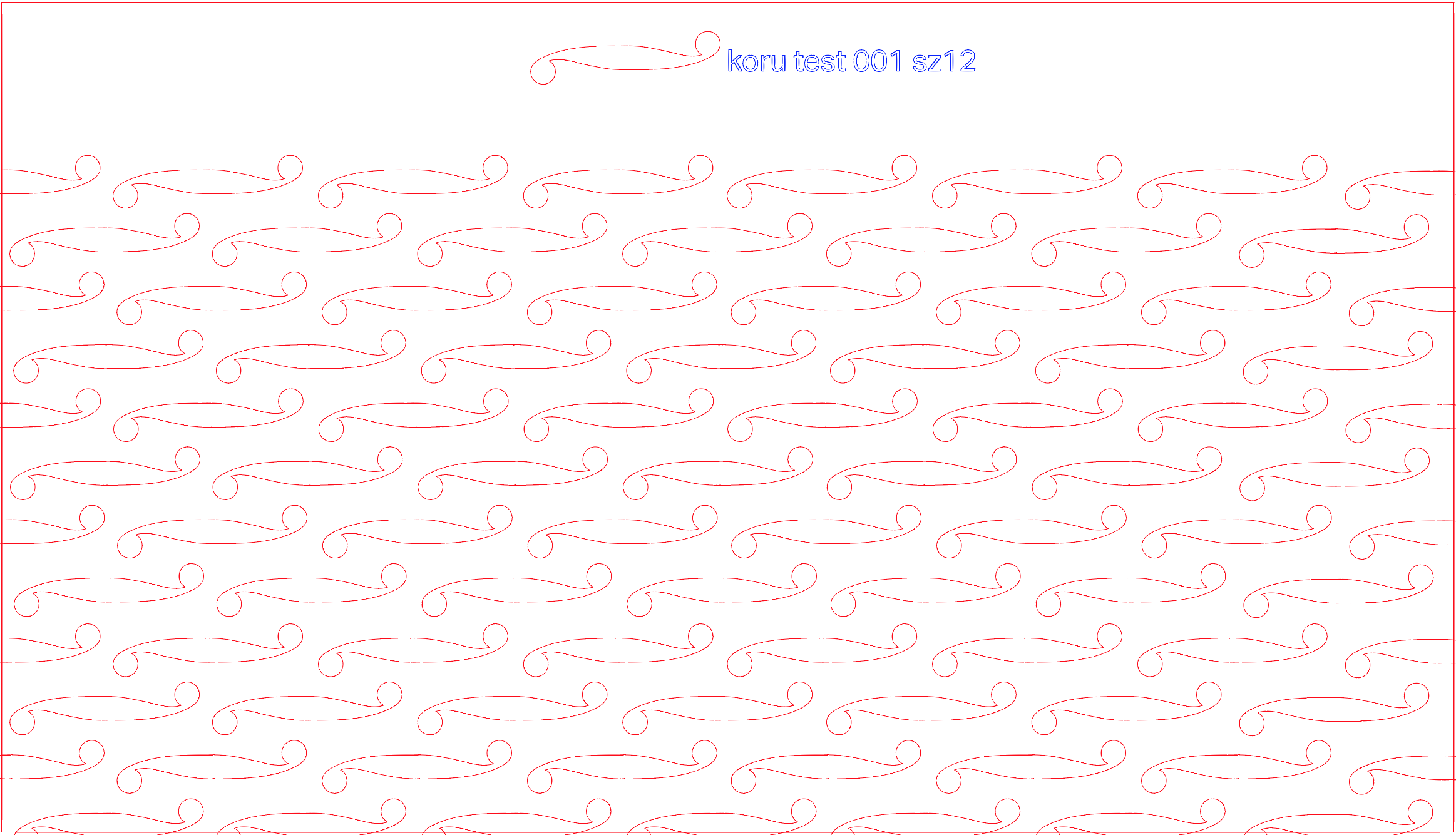

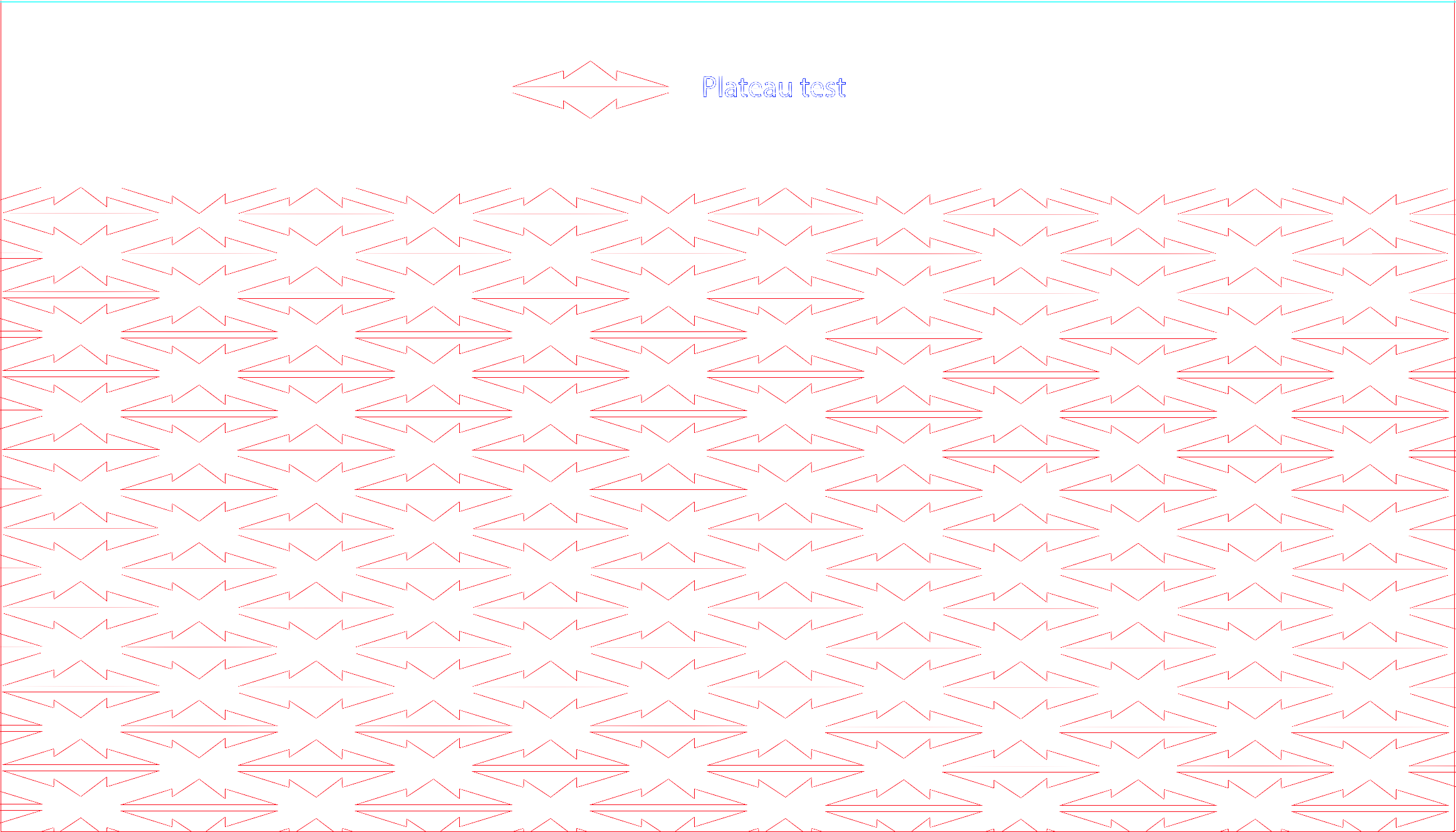

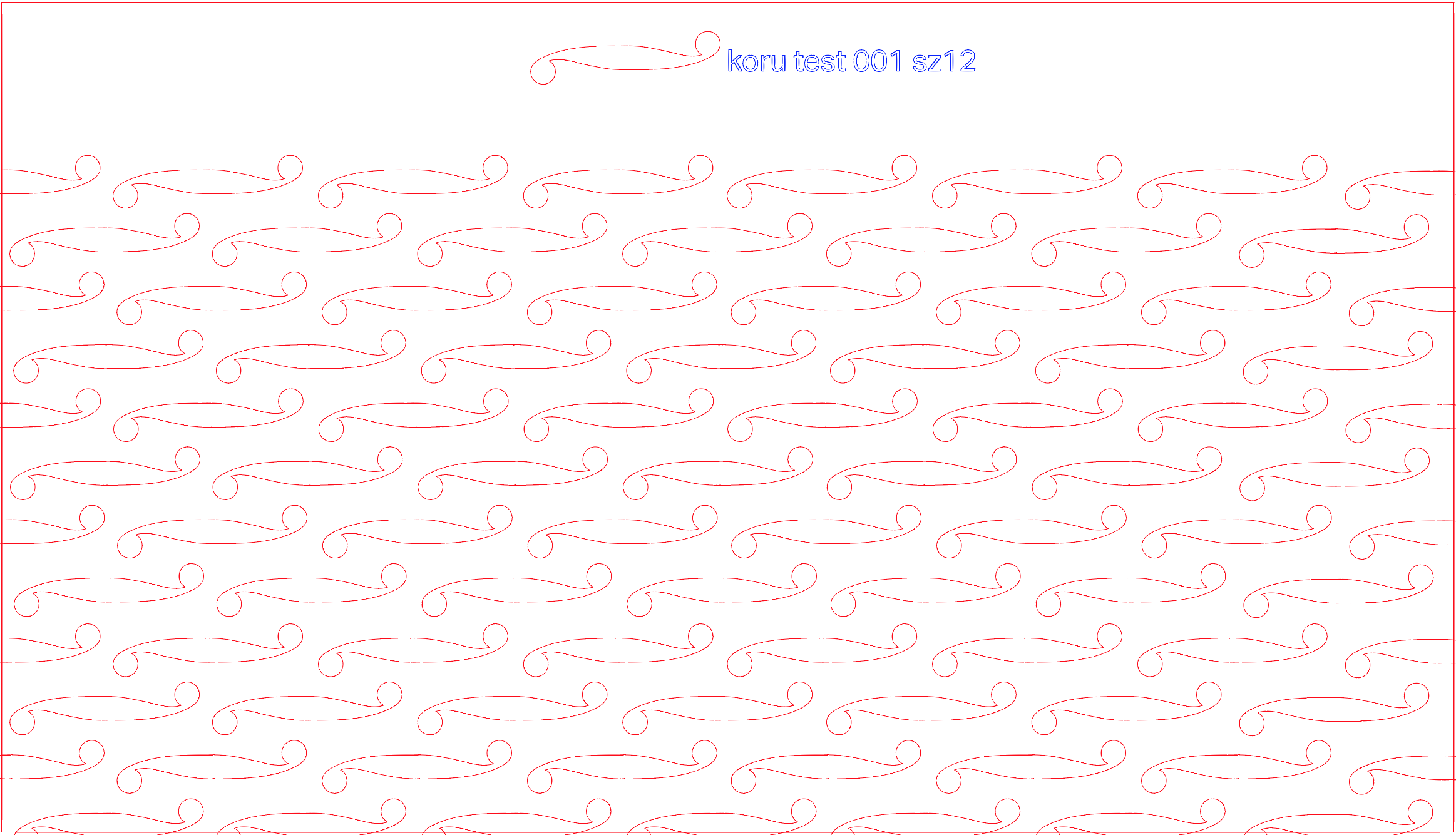

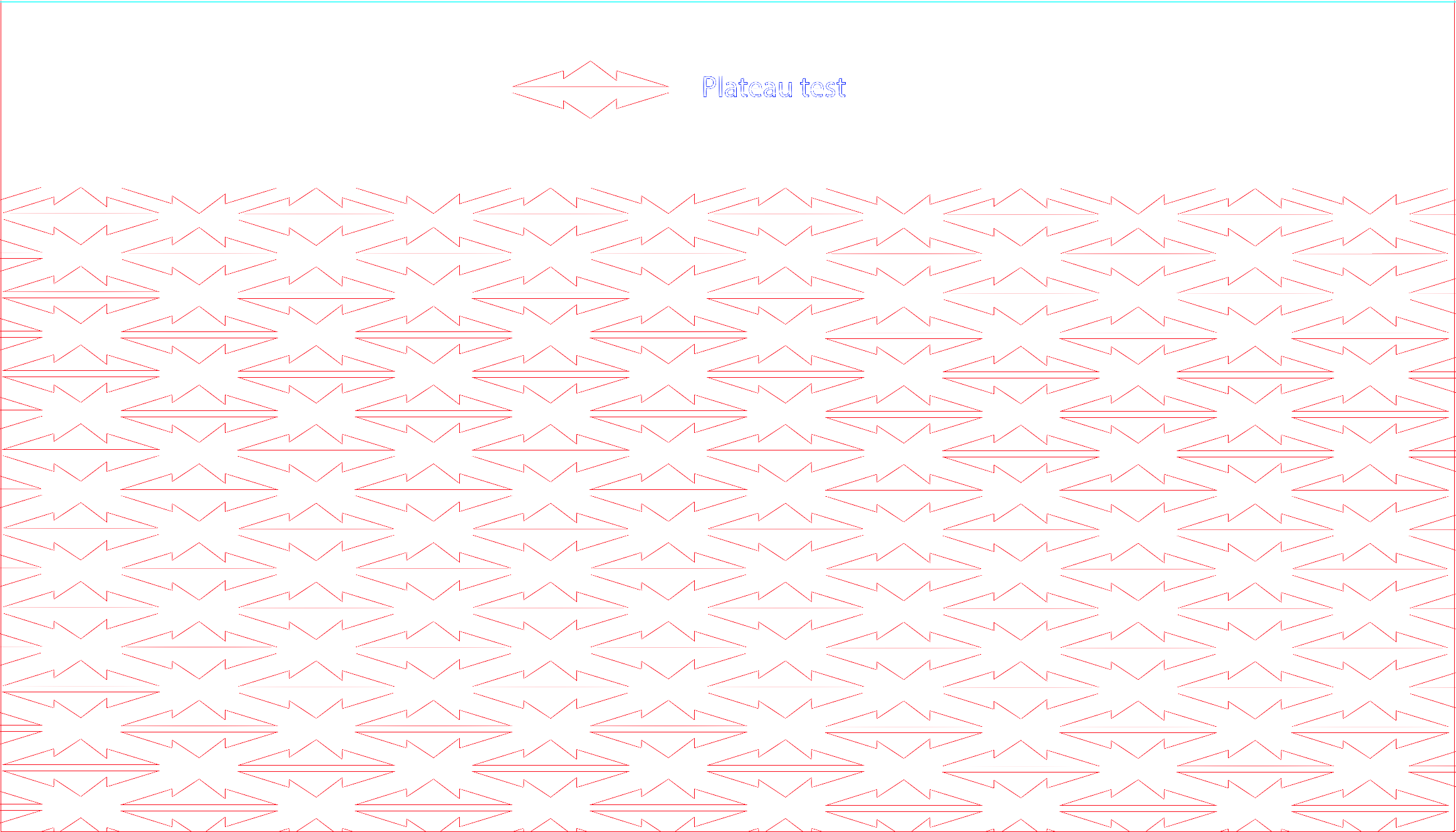

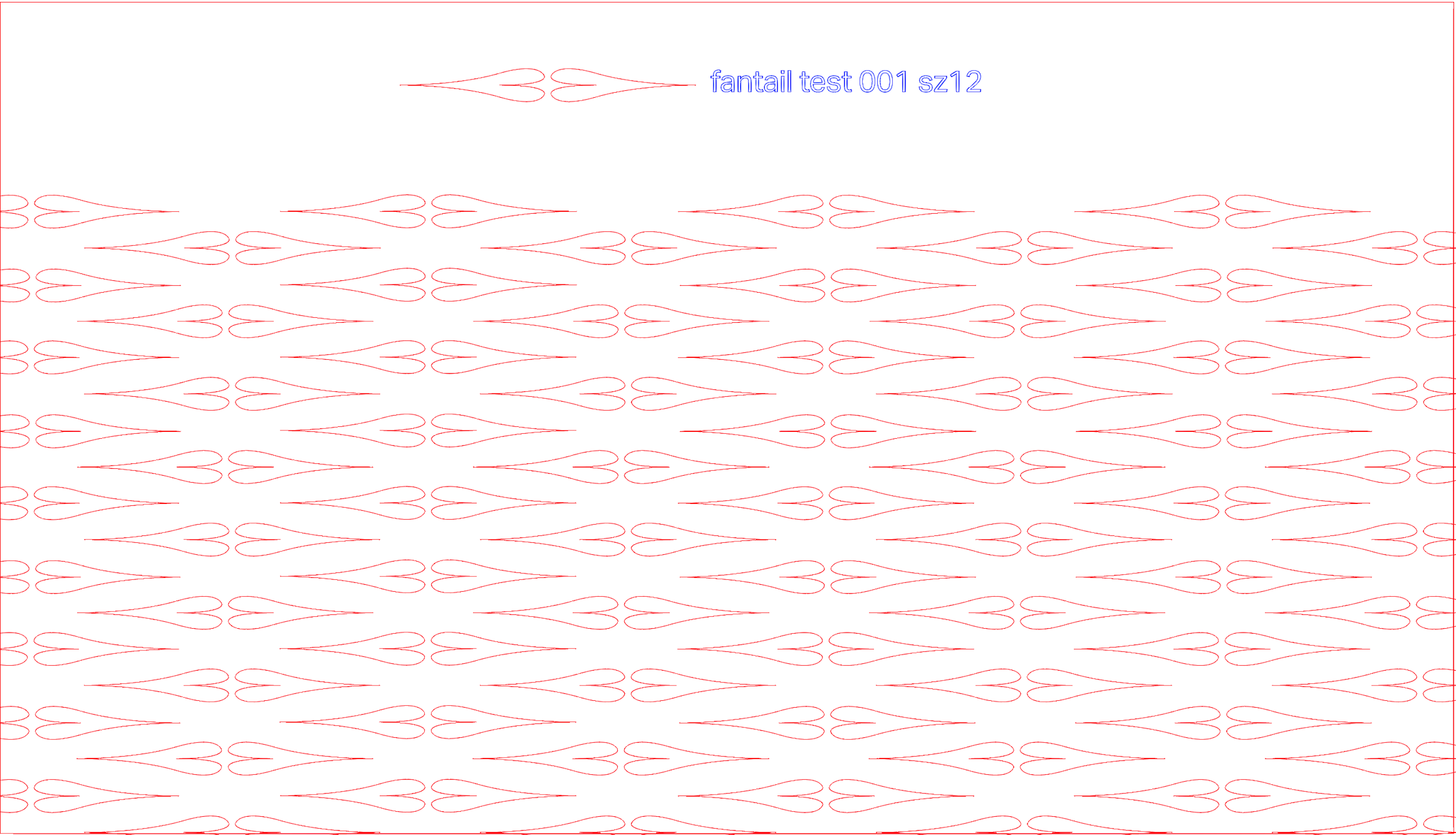

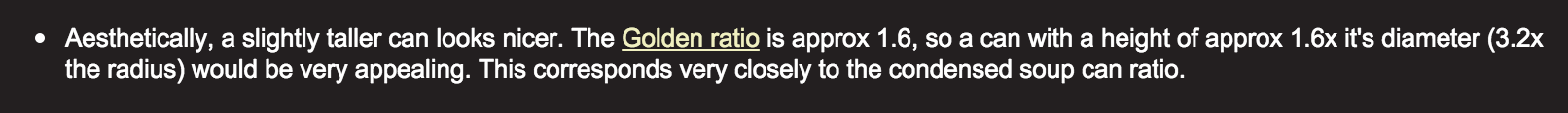

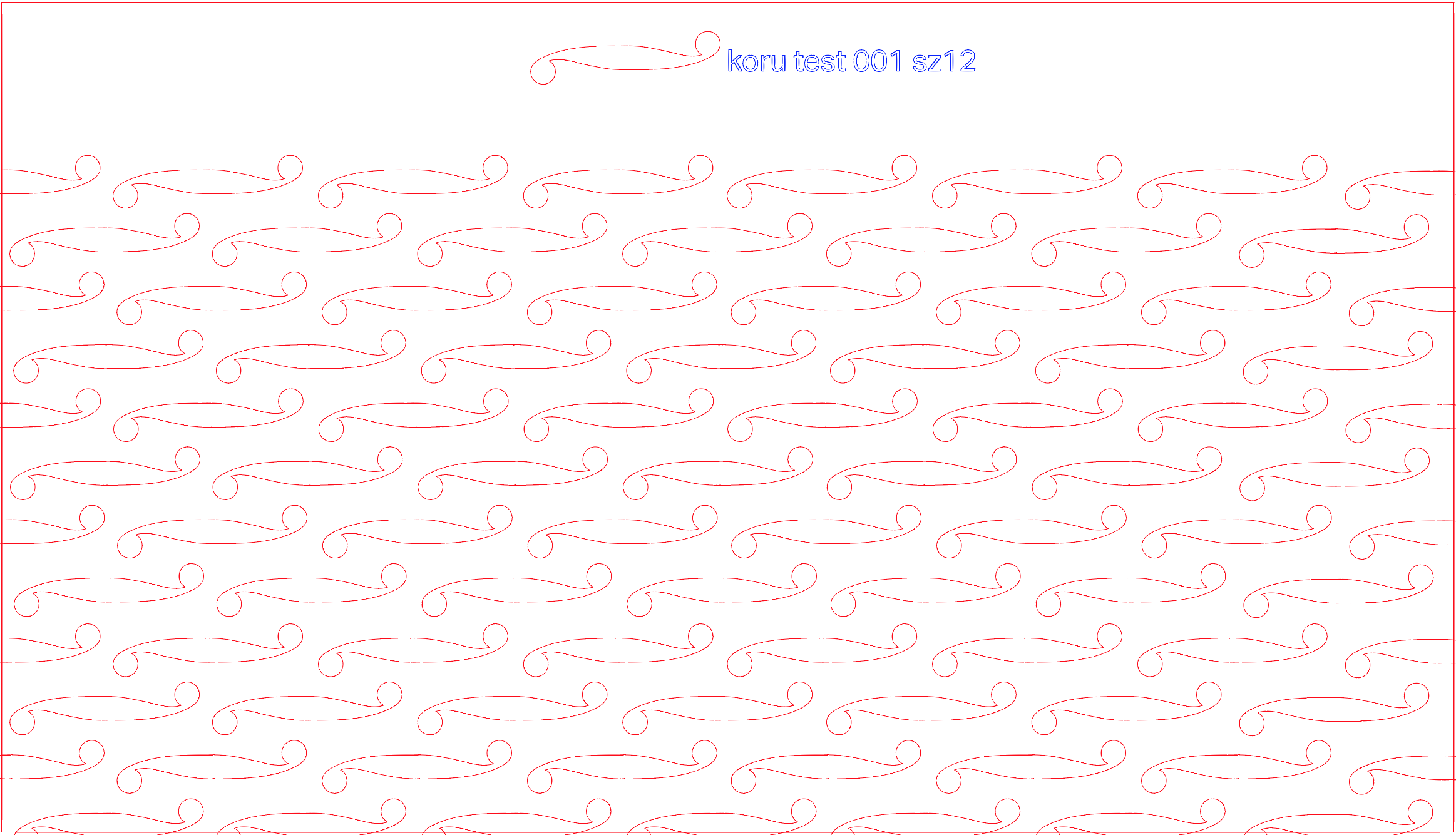

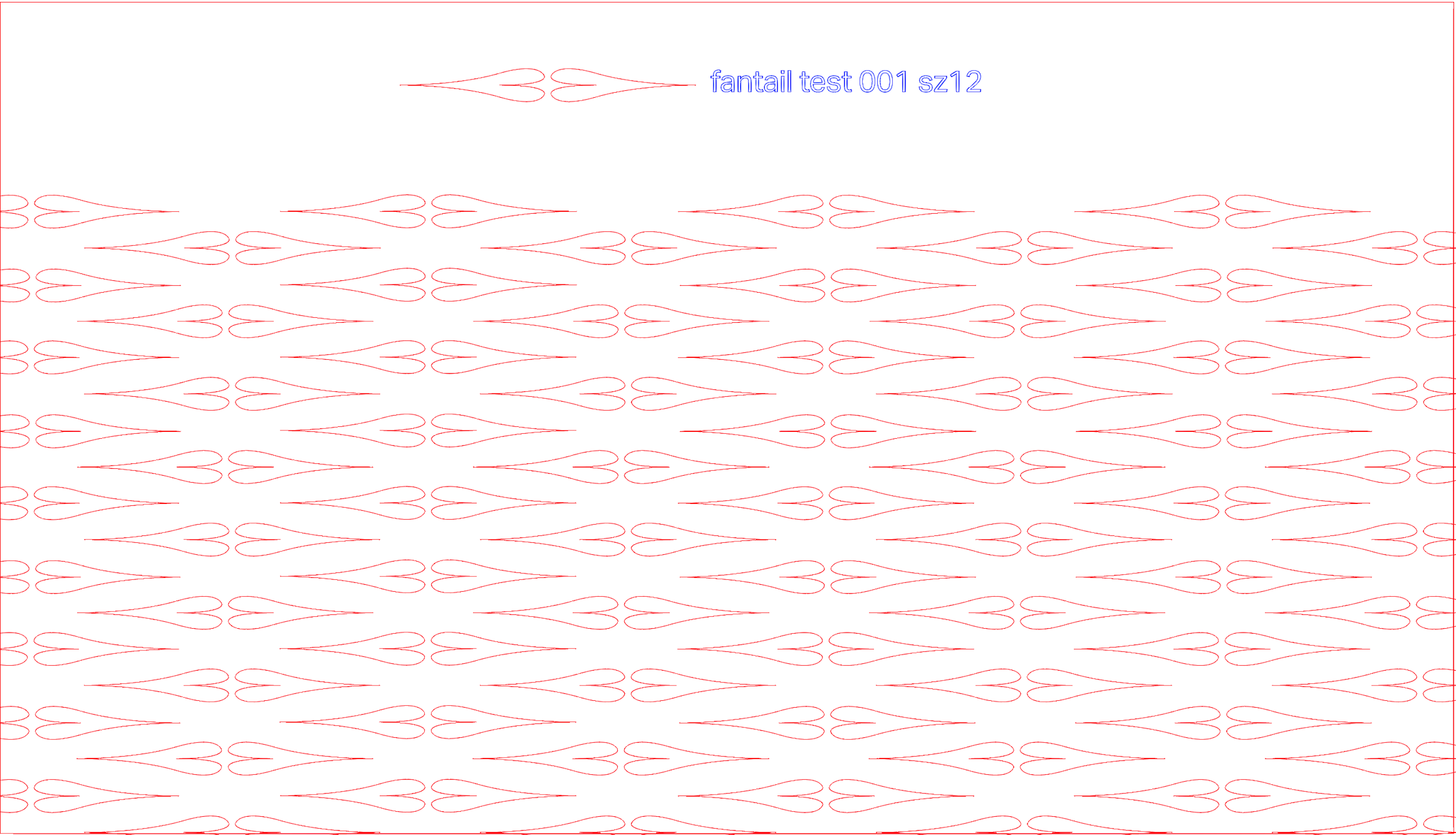

To make our lights unique to us, we’ve used inspiration from nz motifs to create our own kerf patterns. Koru, north island volcanic plateau and also the fantail.

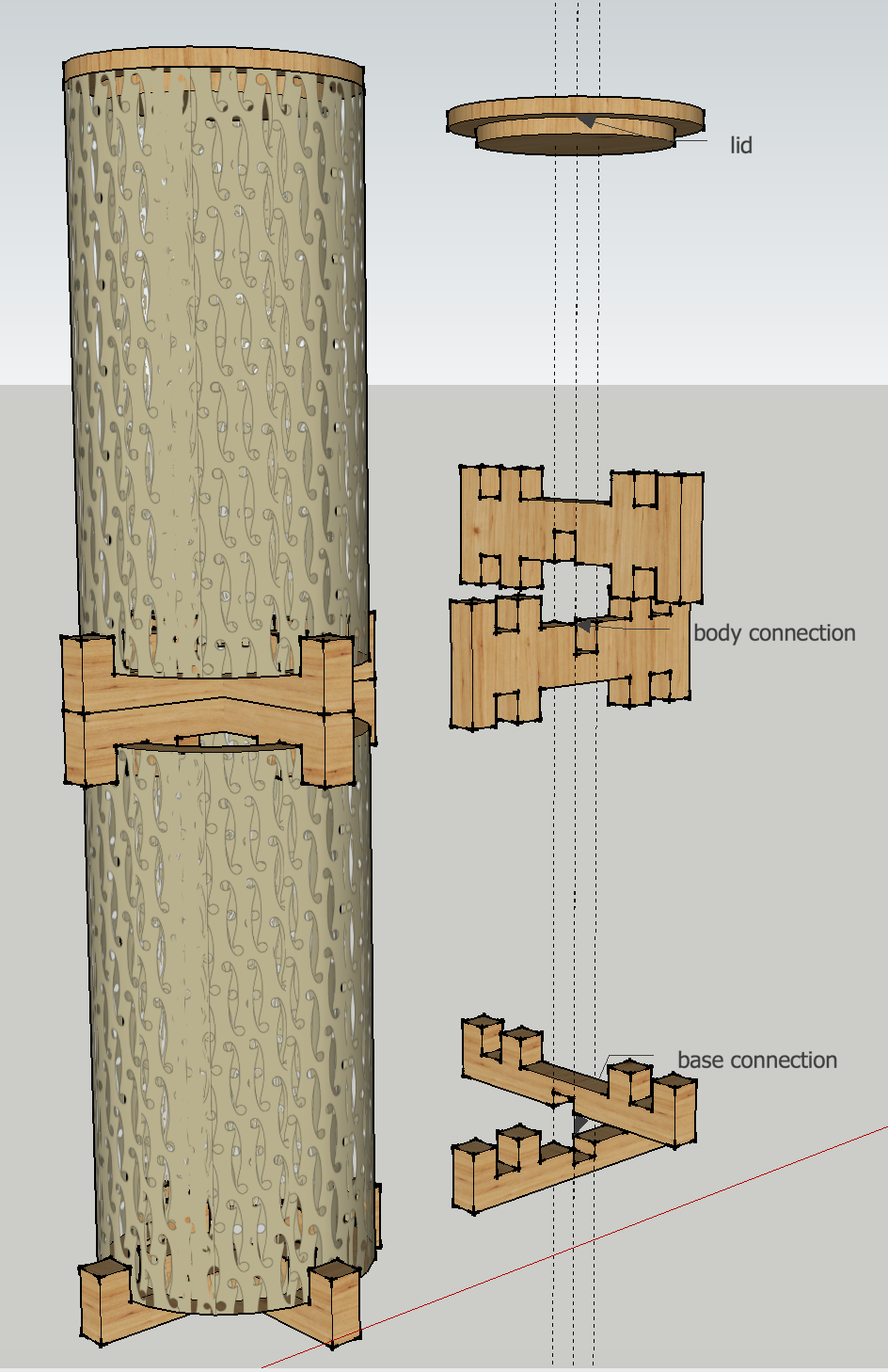

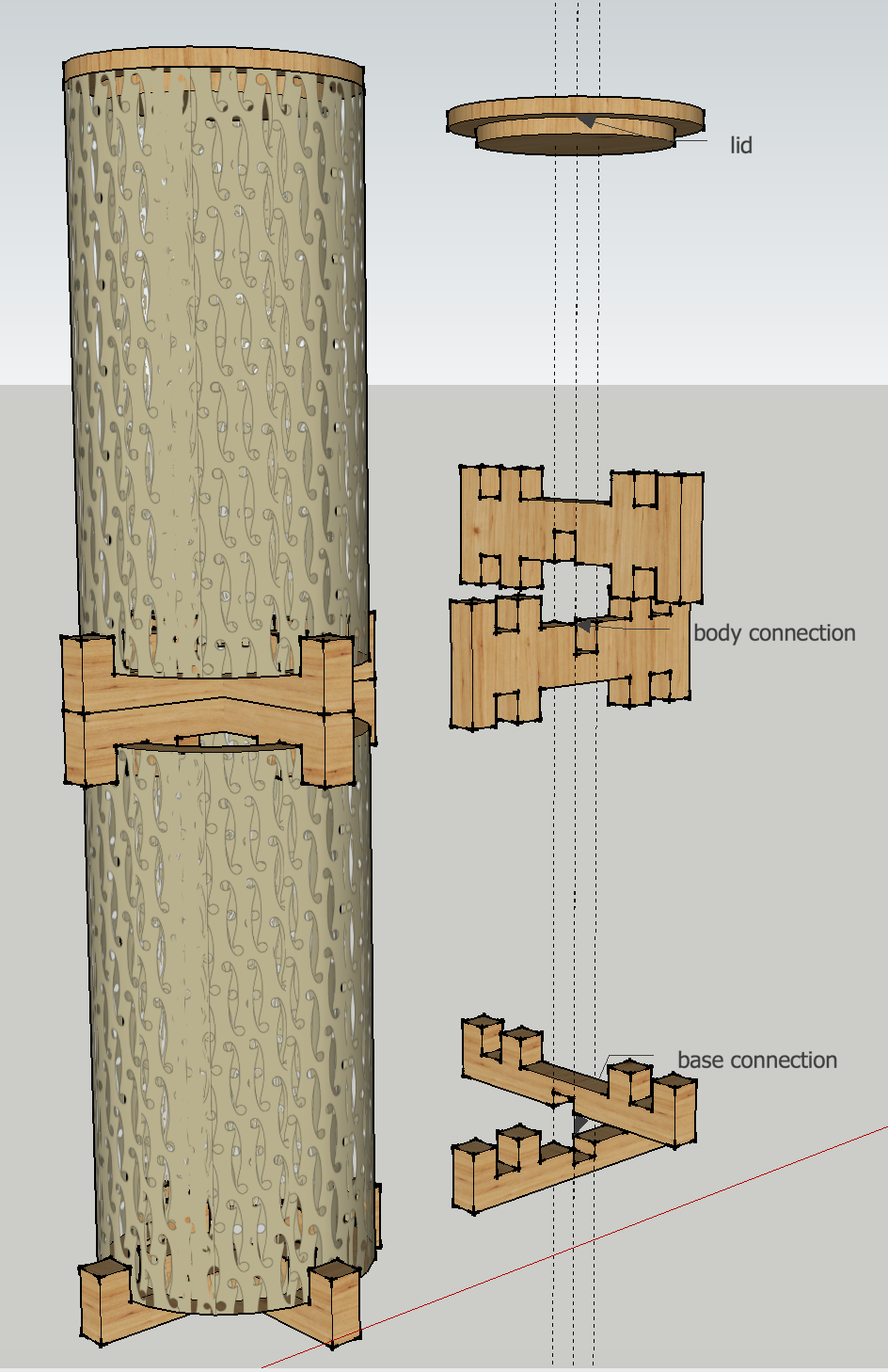

Keeping sustainable we’re wanting to create a light that uses minimal materials and no permanent fixings like glue. So we’ve developed the slot base and connection pieces that the body sits in:

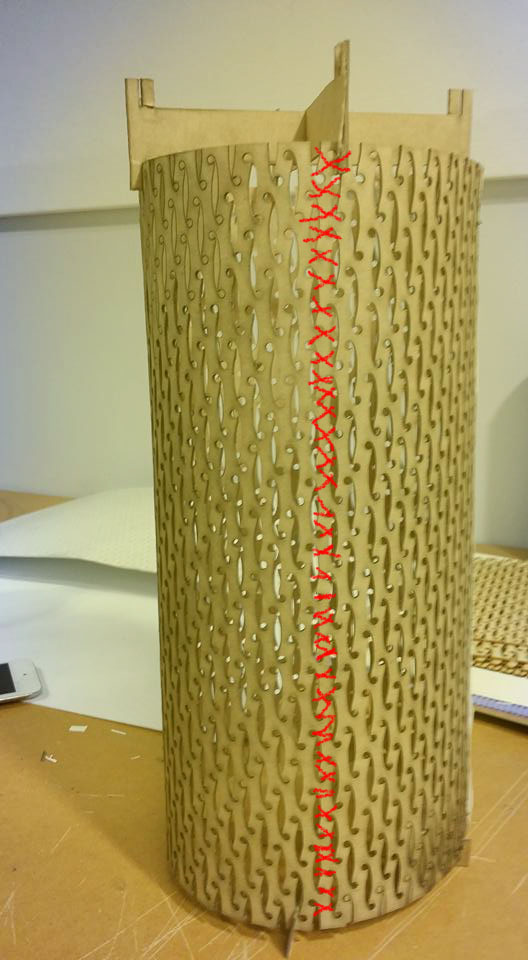

AND now we’re working on a solution for fixing the body to itself in cylinder, an easy way to address this may be using a hemp twine to weave and sew between the kerf gaps.

AND now we’re working on a solution for fixing the body to itself in cylinder, an easy way to address this may be using a hemp twine to weave and sew between the kerf gaps.

This week we’re looking at getting stuck into the electronics and figuring out how the sensor and led’s can work together, on that note the sensors will be located on the lid and the led’s will drop down from the lid inside down to the base.

07 Feb 2016

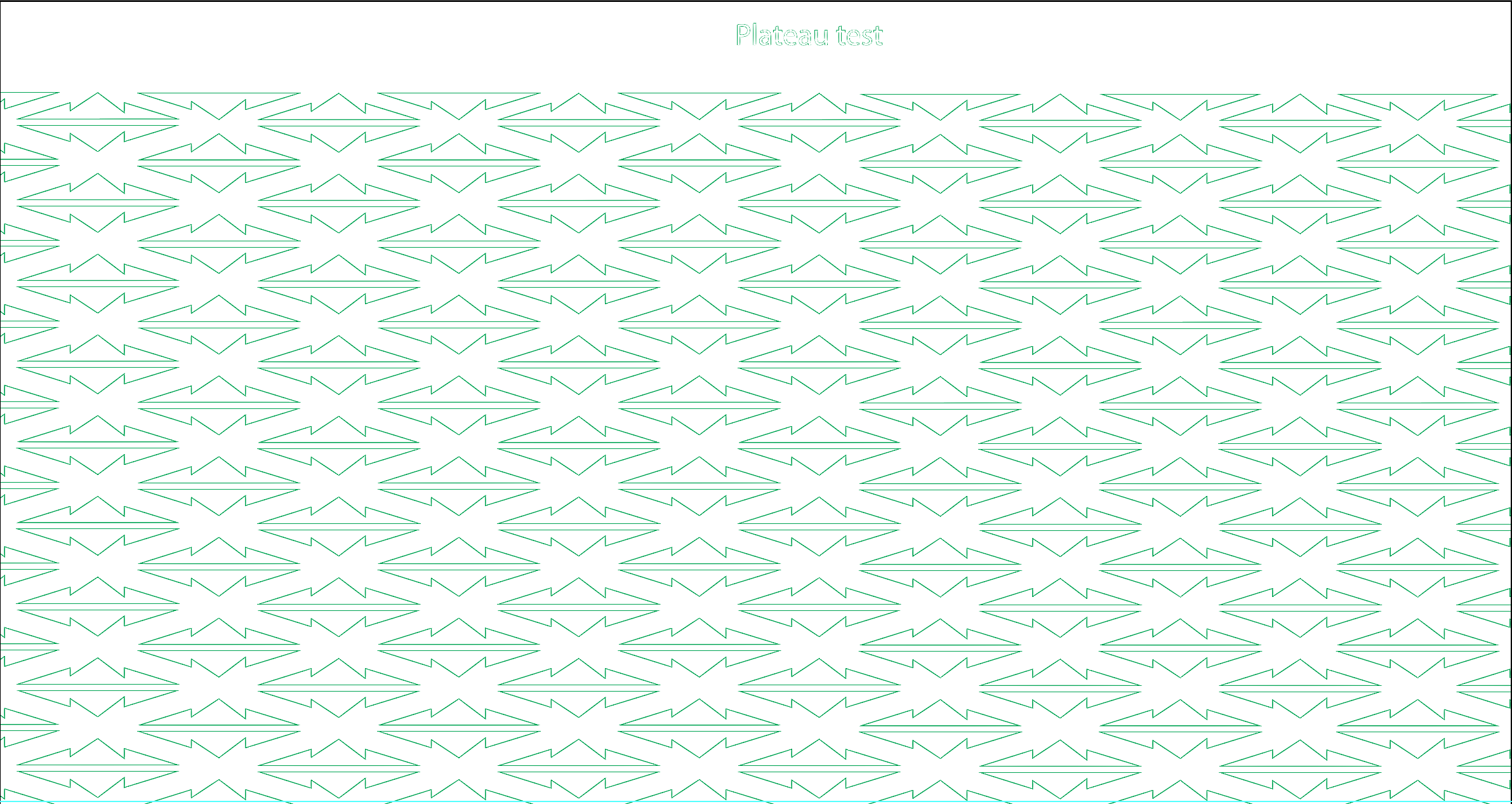

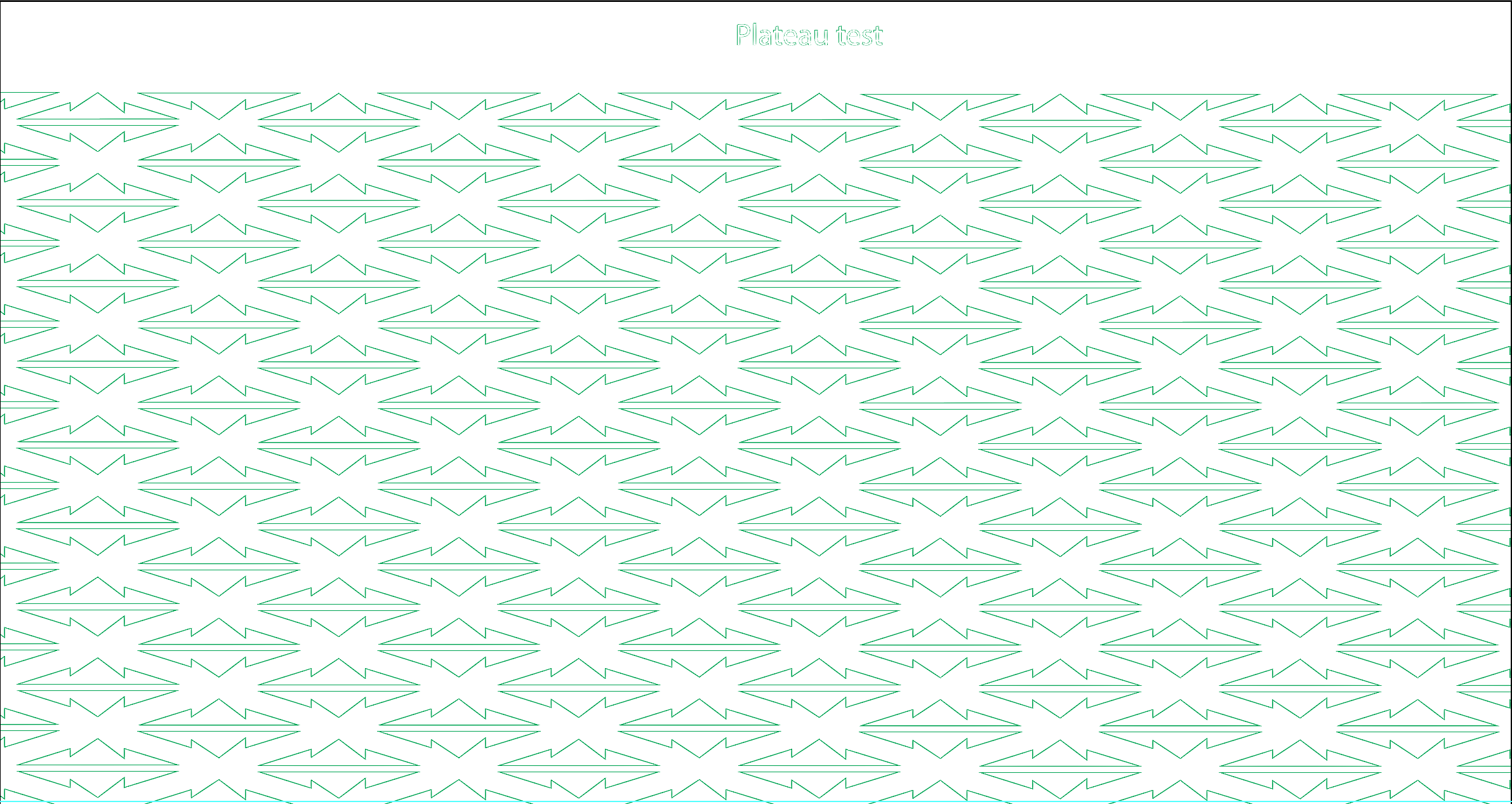

This design is based on the three volcanic mountains in the North Island, Ruapahu, Ngauruhue and Tongariro.

07 Feb 2016

These are three kerf patterns for use on the light shades

KURO:

PLATEAU:

FANTAIL:

AND now we’re working on a solution for fixing the body to itself in cylinder, an easy way to address this may be using a hemp twine to weave and sew between the kerf gaps.

AND now we’re working on a solution for fixing the body to itself in cylinder, an easy way to address this may be using a hemp twine to weave and sew between the kerf gaps.