10 Feb 2016

In previous processes we have looked into:

Nz Motif Pattern designs, How the pattern bends and creates shadows

the joints that holds cylinders together,

the way to hold both edges together,

Golden ratio to make our model stable (size of the model),

setting up for laser cutting bamboo (there were no setting for bamboo)

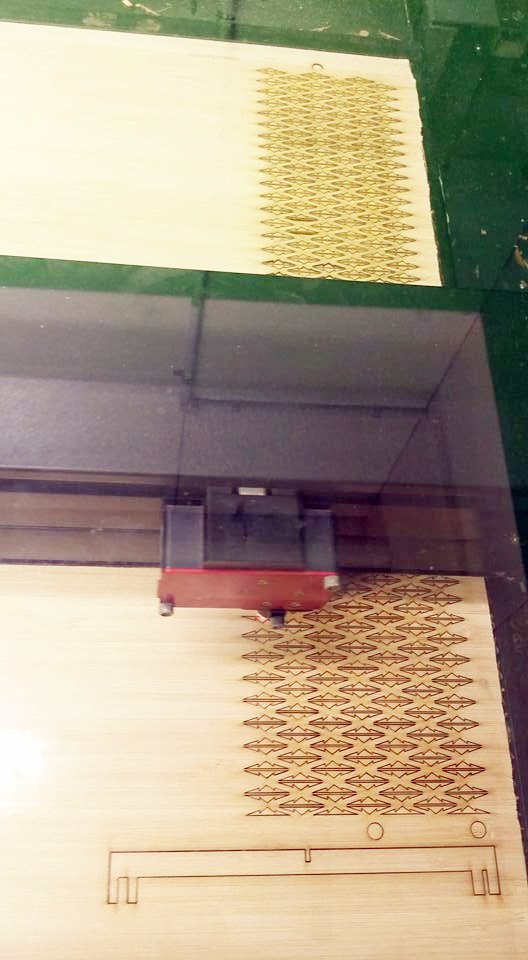

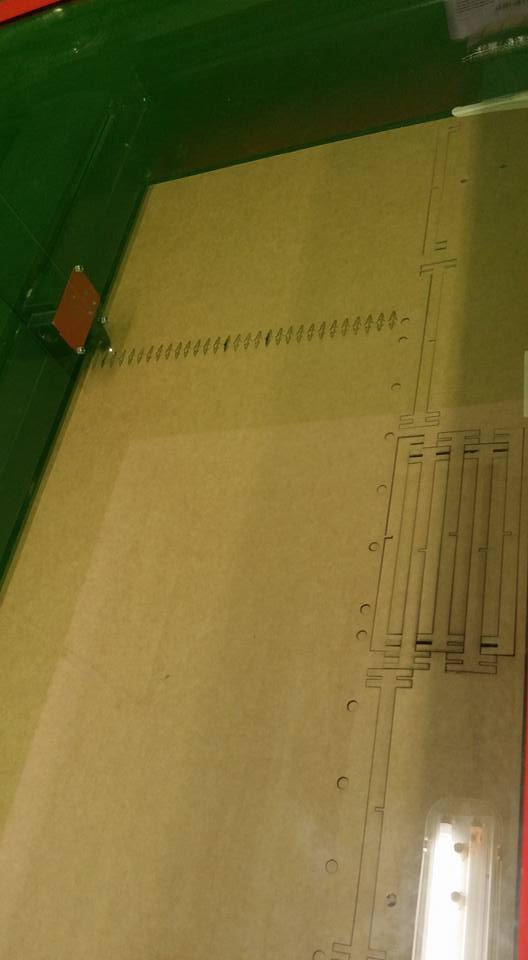

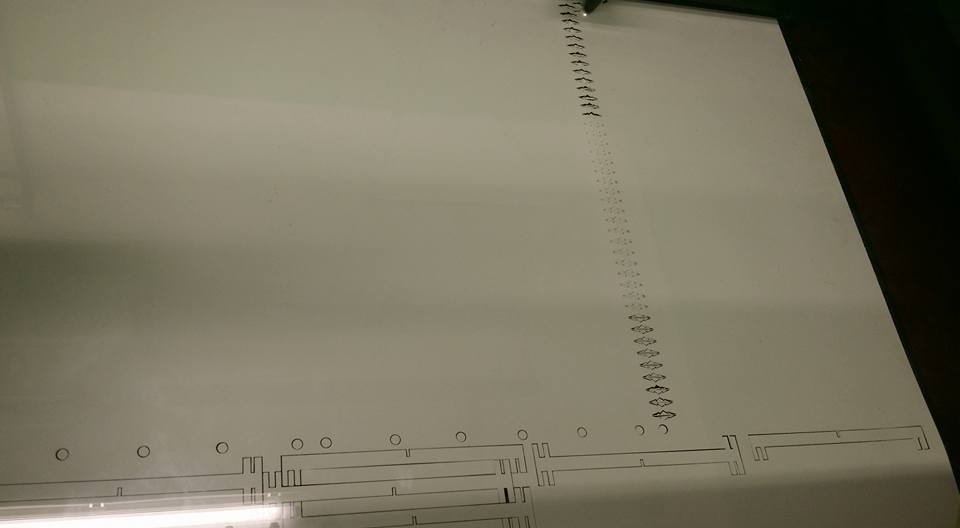

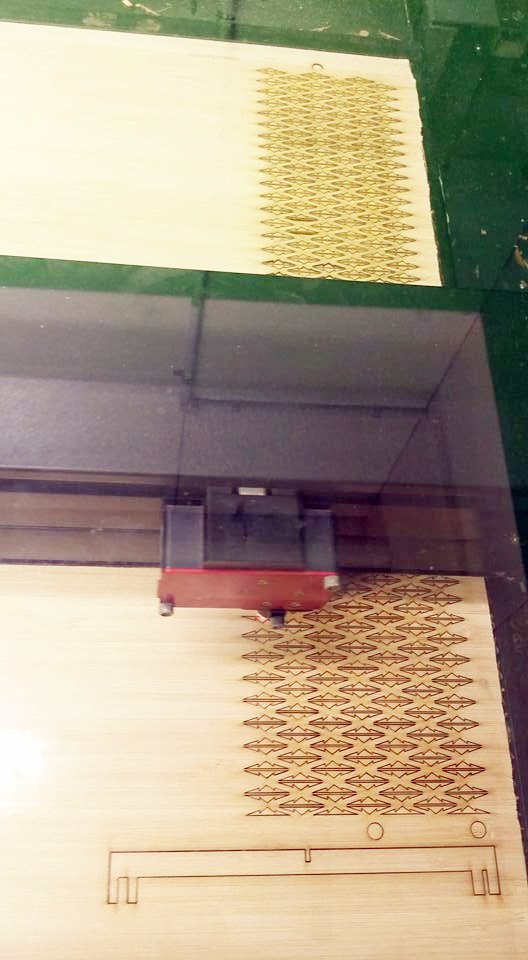

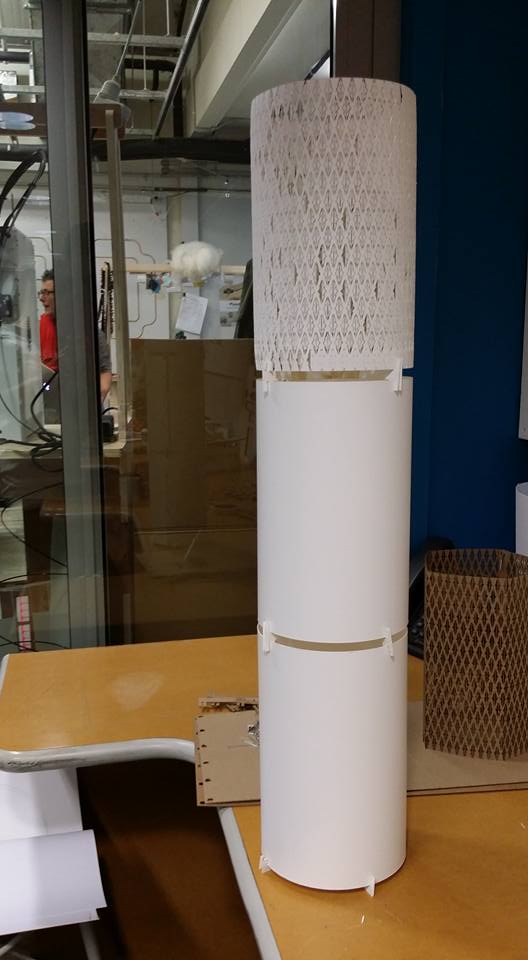

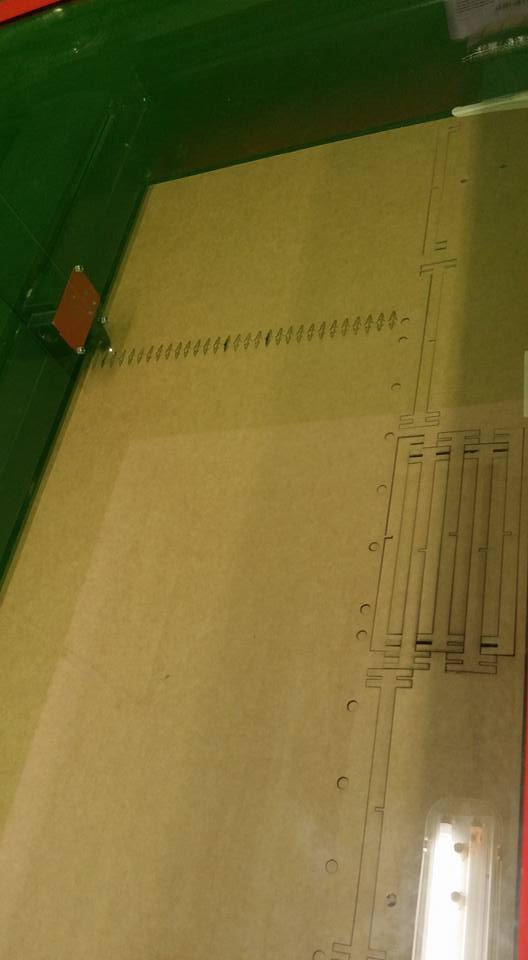

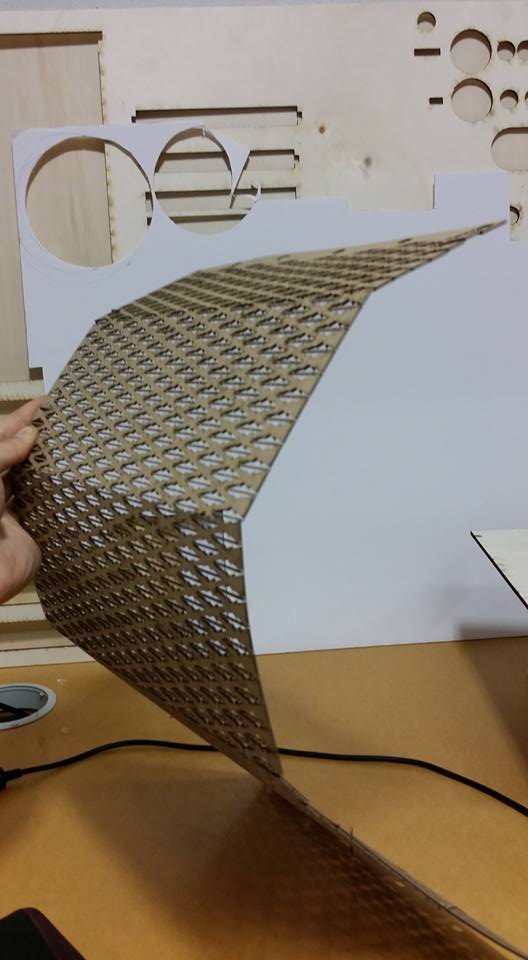

Finally this is the first attempt to cut bamboo sheet in real lamp size.

All the settings are right so everything has cut through well.

Finally this is the first attempt to cut bamboo sheet in real lamp size.

All the settings are right so everything has cut through well.

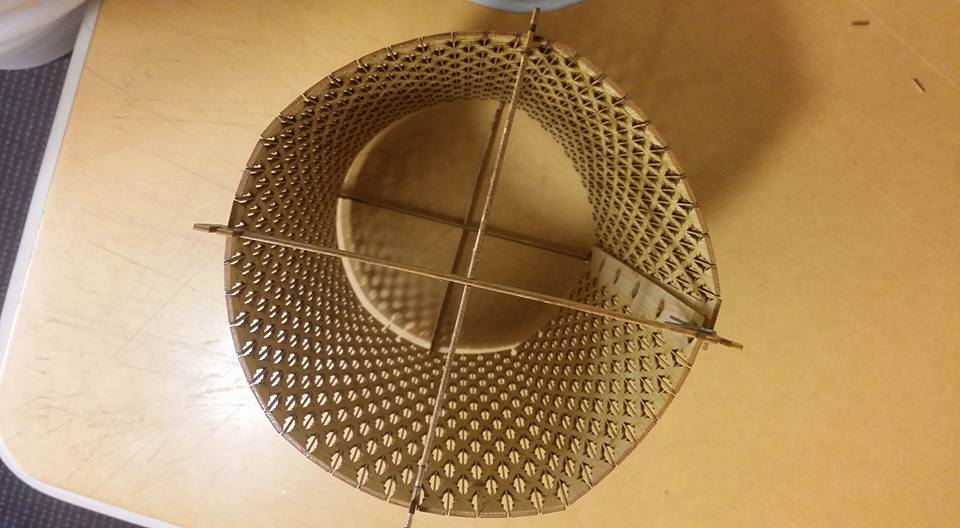

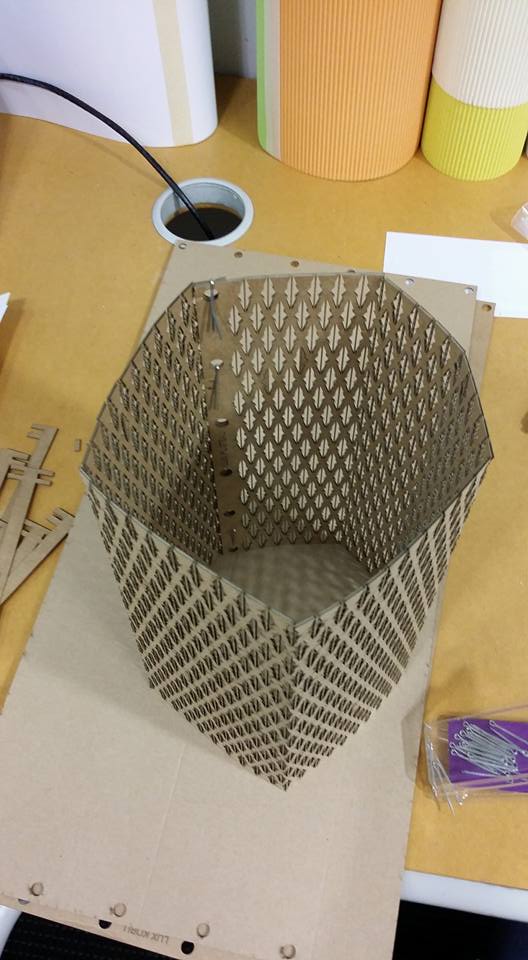

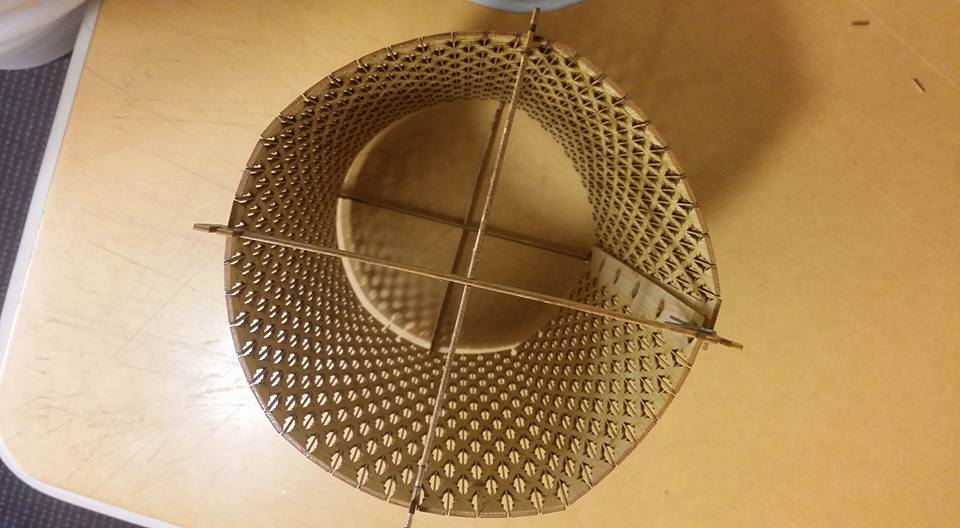

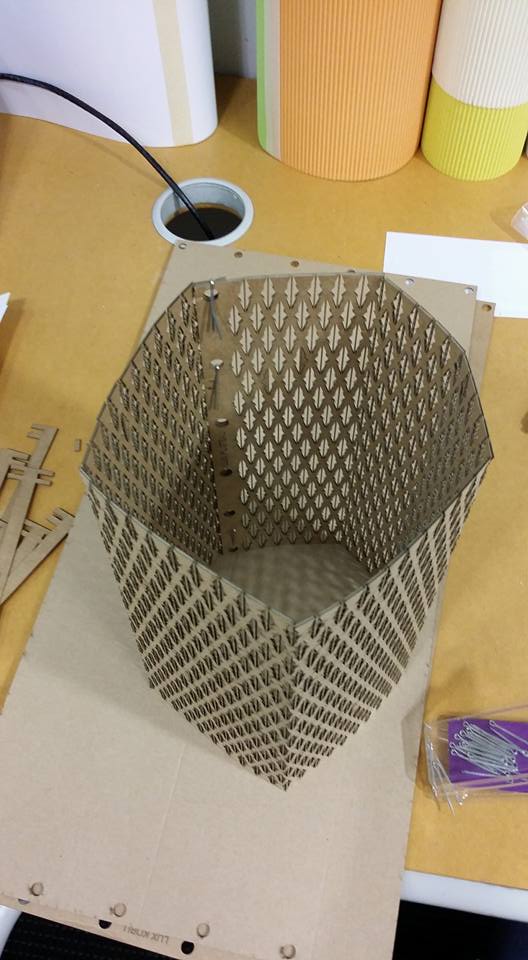

Here is our prototype, our joints are working well and connecting edges with pins are fine as well

Here is our prototype, our joints are working well and connecting edges with pins are fine as well

the only problem I think is that if you see the shape of cylinder it isn’t actually round as we want it to be. The resolution for this is to not cut the pattern until the edge so that it doesn’t change the roundness of the cylinder. (changing the layout of the pattern might solve this problem)

the only problem I think is that if you see the shape of cylinder it isn’t actually round as we want it to be. The resolution for this is to not cut the pattern until the edge so that it doesn’t change the roundness of the cylinder. (changing the layout of the pattern might solve this problem)

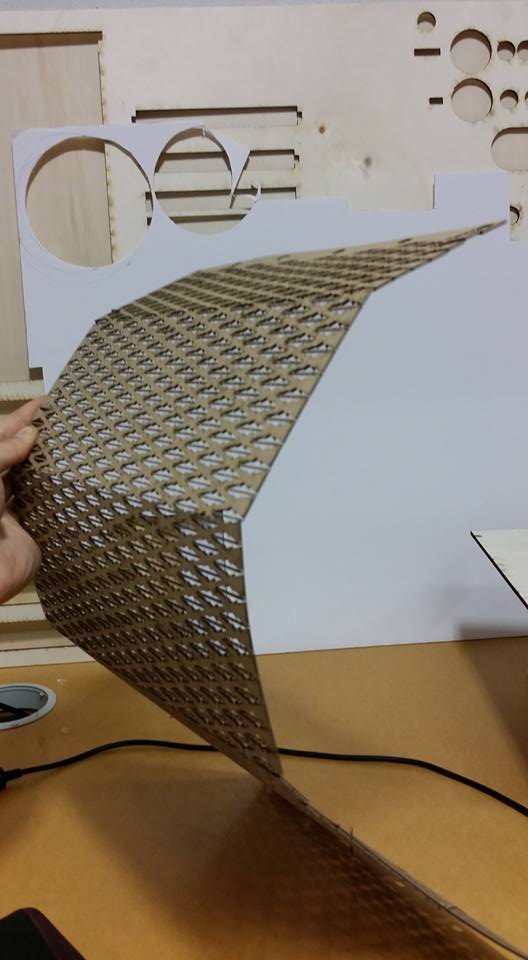

Though our pattern bends quite well regarding that it is a wood.

Though our pattern bends quite well regarding that it is a wood.

The height of the lamp is 250mm (25cm) and if we top 2 more cylinders on top it will be 75cm in total with approx 5cm gap in total. (80cm height in total)

Fin was having a problem with the fabduino program so there is no process on arduino yet but he will post later on about his process.

Our next process will be looking into the lid that would sit on top of the cylinder.

The lid will have 2 sensors, fabduino, LED light attached to it and we are thinking of making a slot for those to perfectly fit in the lid (so nothing hangs out of the lamp).

10 Feb 2016

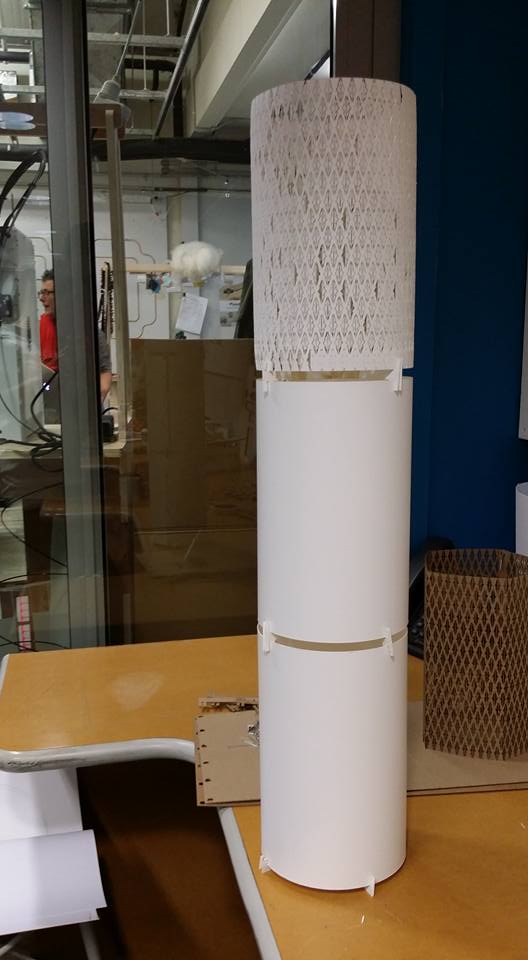

so this is what I have made out of Poly. It bends really well therefore I had no problem connecting both edges together

so this is what I have made out of Poly. It bends really well therefore I had no problem connecting both edges together

Even so I couldn’t test the joint parts well (because it was too weak to hold cylinders together)

Even so I couldn’t test the joint parts well (because it was too weak to hold cylinders together)

The next process that I am planning to do is laser cutting the actual bamboo sheet to see if it bends well.

Fin was having a problem with the fabduino program so there is no process on arduino yet but he will post later on about his process.

10 Feb 2016

Today we wanted to see if our models would stand nicely as we have expected therefore we were planning to cut out three cylinder models to top it up together.

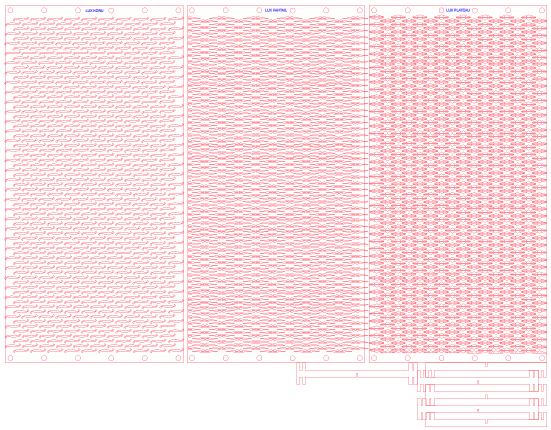

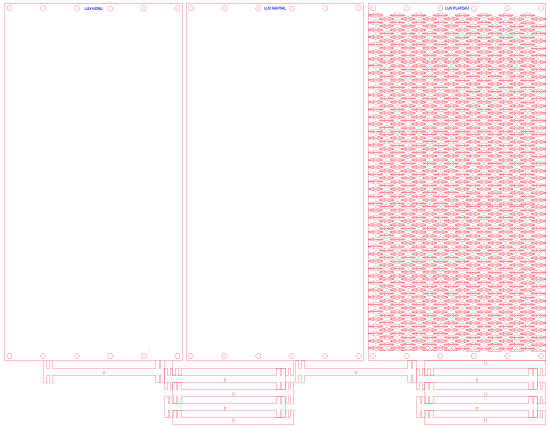

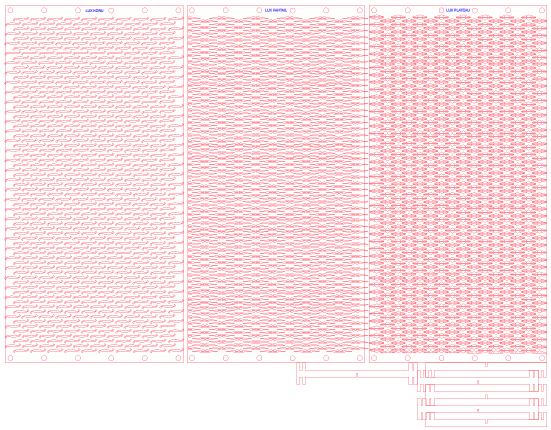

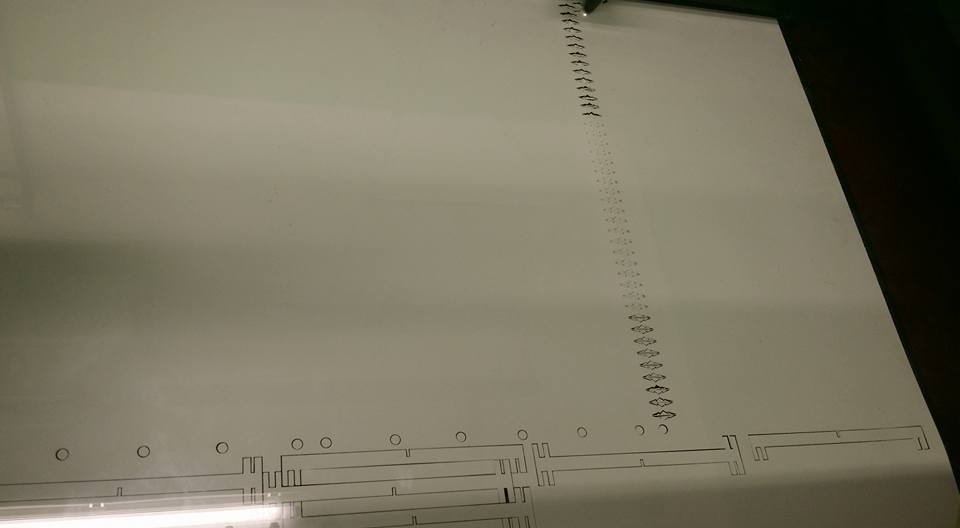

Here is the original illustration file from Kate

Here is the original illustration file from Kate

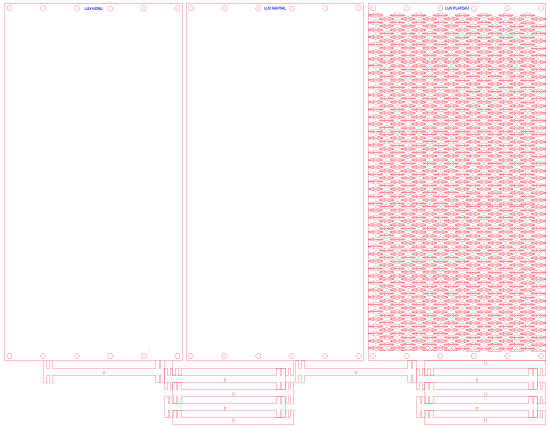

and here are the blanc file that I have made to reduce down the laser cutting time.

and here are the blanc file that I have made to reduce down the laser cutting time.

The laser cutting of the corrugated cardboard was ok there were no charcoal marks and the cuts were clean.

The laser cutting of the corrugated cardboard was ok there were no charcoal marks and the cuts were clean.

We didn’t have other cardboard to use so we used corrugated cardboard

We didn’t have other cardboard to use so we used corrugated cardboard

but the problem was that this material folded badly and made edges instead of bending nicely into cylinder shape

but the problem was that this material folded badly and made edges instead of bending nicely into cylinder shape

We are cutting a poly on the lasercutter but we had many issues on this material as well because when laser cut out the shape it stuck together right away.

We have increased the power on the setting manualy and it is giving us a cut but I don’t think it will be clean as we have cut cardboards. We are planning to cut our bamboo sheet when all the sized are right because we know that the Kerfpattern is working on our material.

We are cutting a poly on the lasercutter but we had many issues on this material as well because when laser cut out the shape it stuck together right away.

We have increased the power on the setting manualy and it is giving us a cut but I don’t think it will be clean as we have cut cardboards. We are planning to cut our bamboo sheet when all the sized are right because we know that the Kerfpattern is working on our material.

Settings changed for cutting poly 0.65mm

power=45%

speed=12%

09 Feb 2016

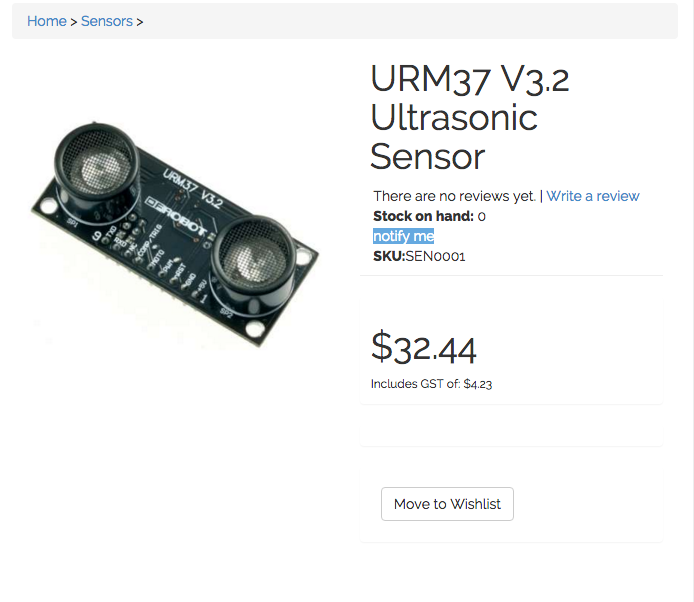

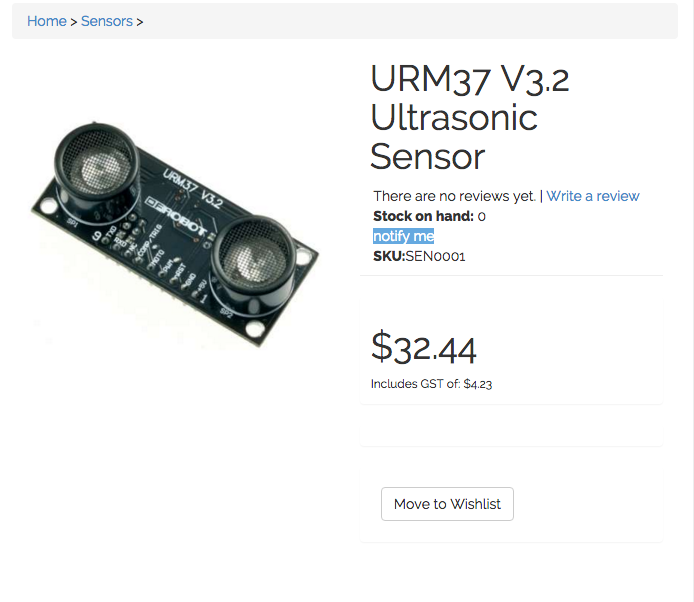

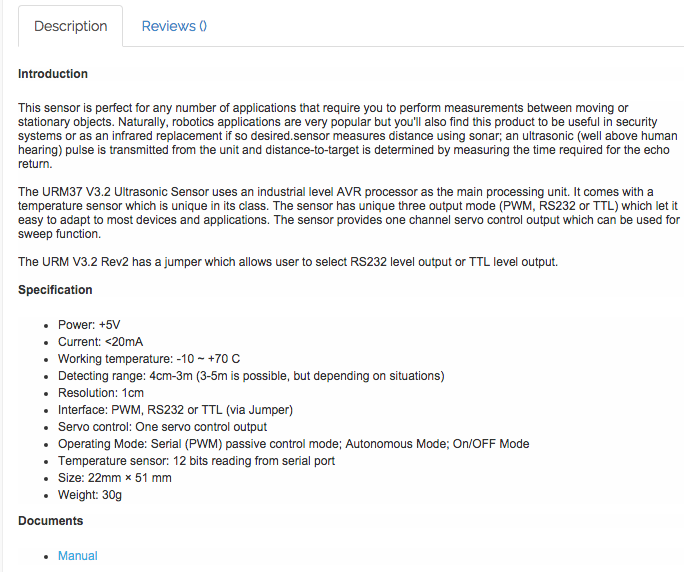

We want sensors which will detect our movement from 4cm~3m far therefore we have found this sensor URM37 V3.2 Ultrasonic sensor.

We want sensors which will detect our movement from 4cm~3m far therefore we have found this sensor URM37 V3.2 Ultrasonic sensor.

It is currently out of stock at the moment so we would have to find similar sensor around Wellington but this kind of sensors are what we want to get.

It is currently out of stock at the moment so we would have to find similar sensor around Wellington but this kind of sensors are what we want to get.

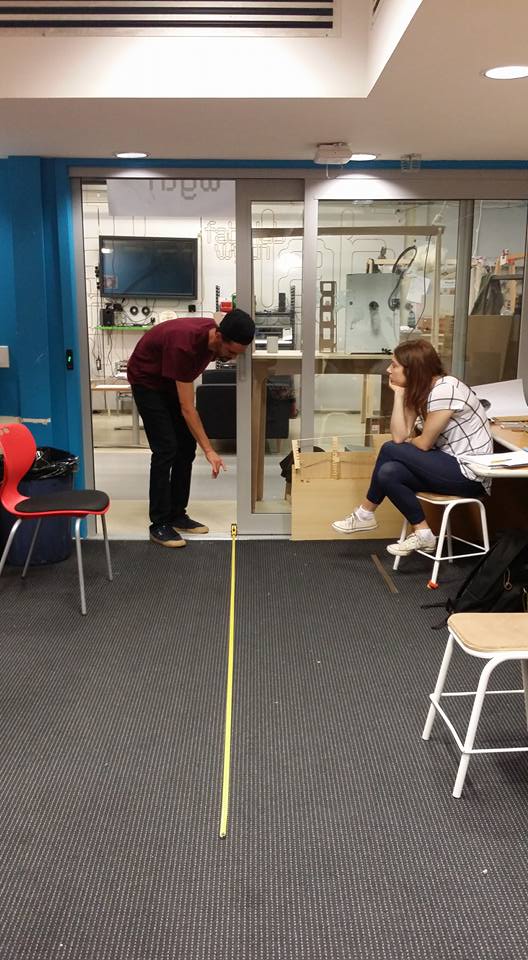

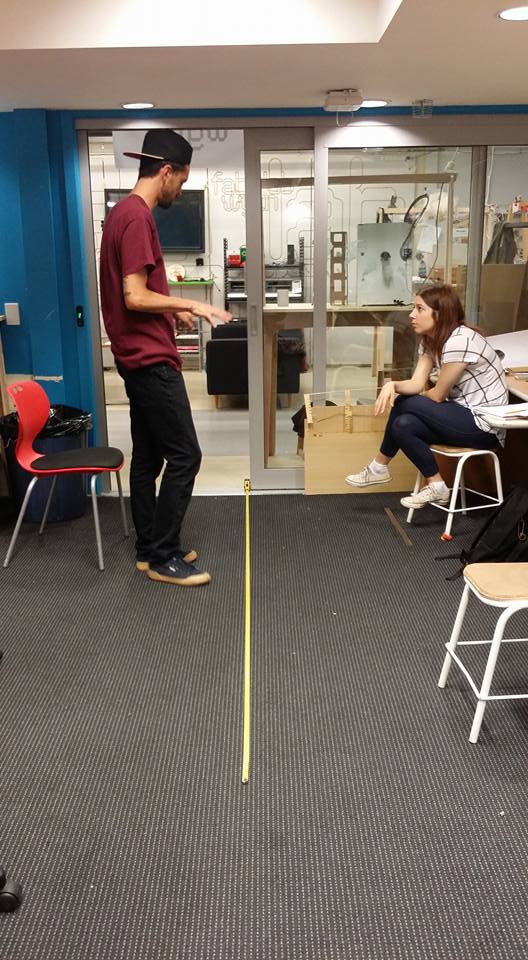

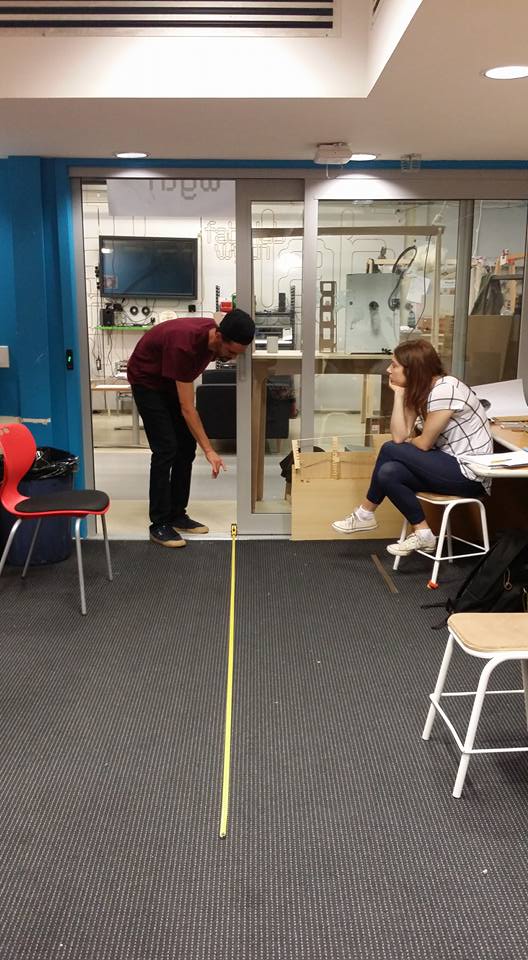

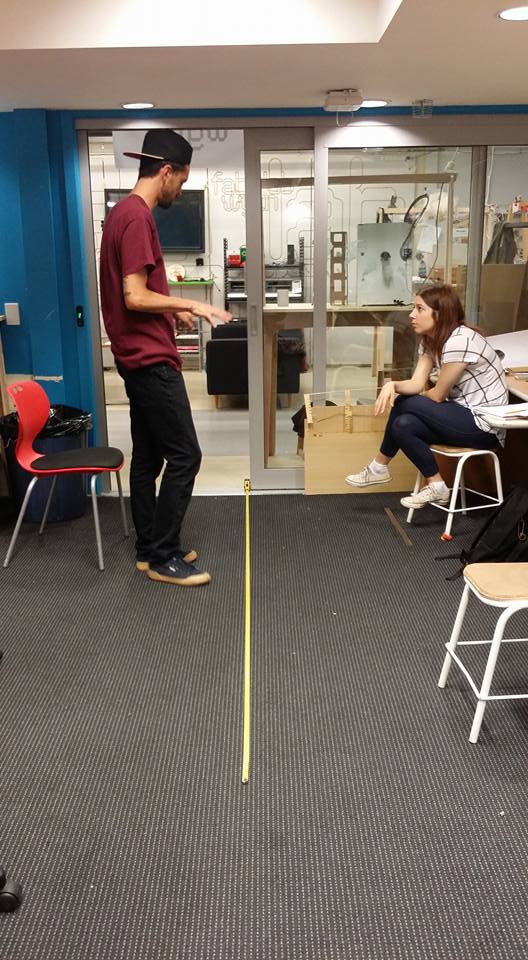

This would be about 3m far, our group figured out the measurement by the measuring tape.

This would be about 3m far, our group figured out the measurement by the measuring tape.

We are planning to get it before this week so we could have a go at making a lid in the weekend or earlier next week.

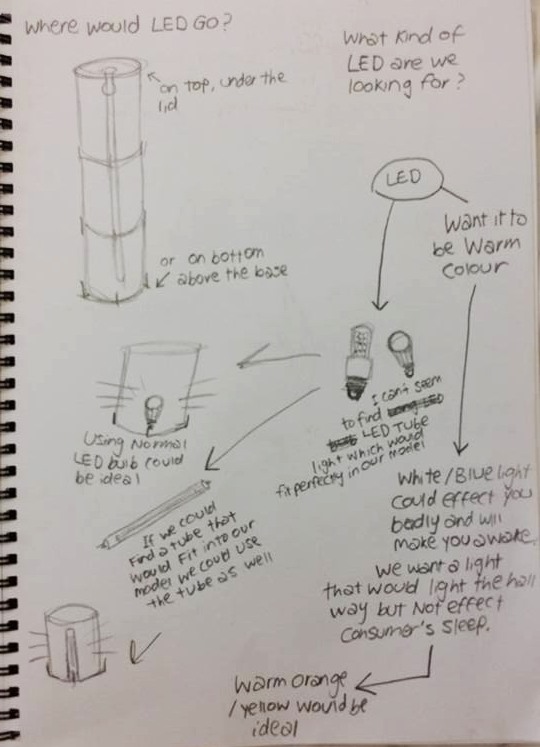

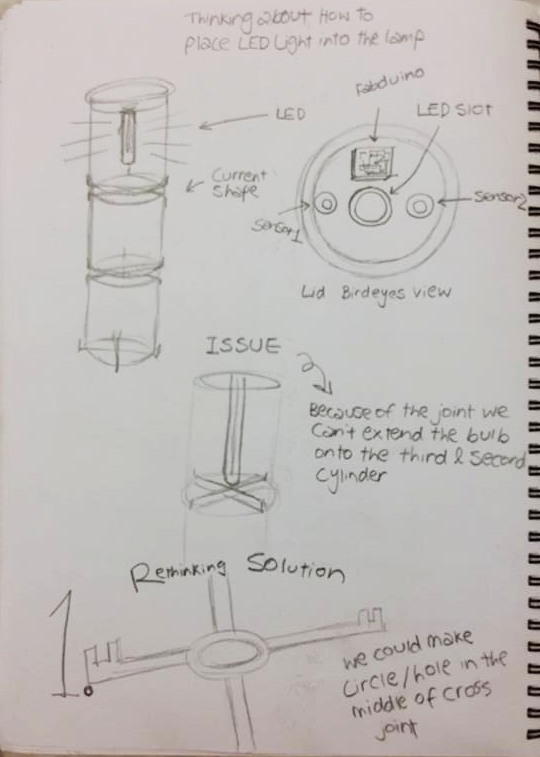

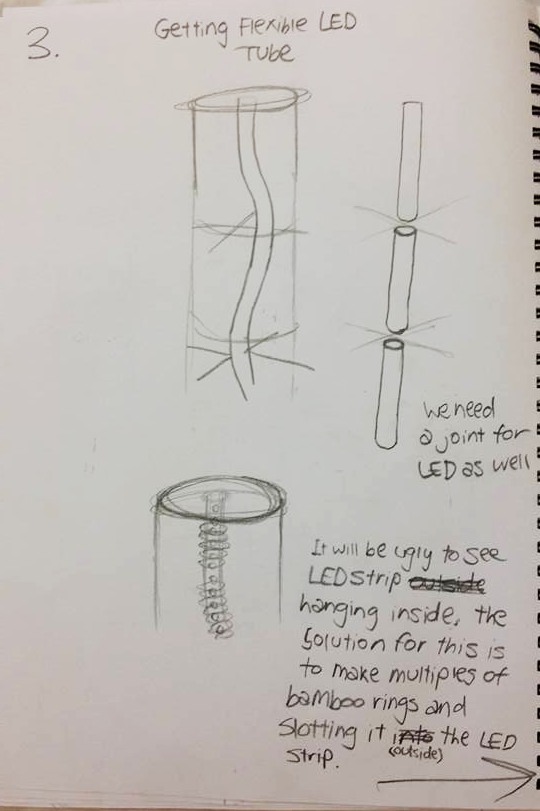

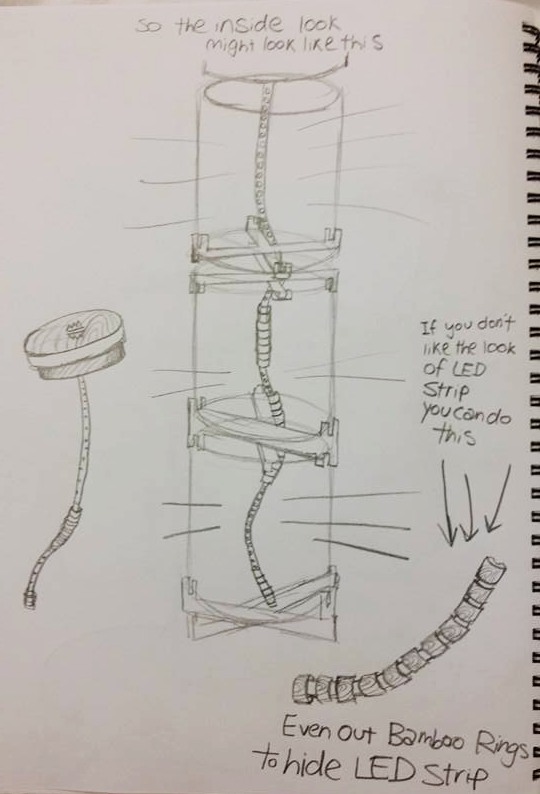

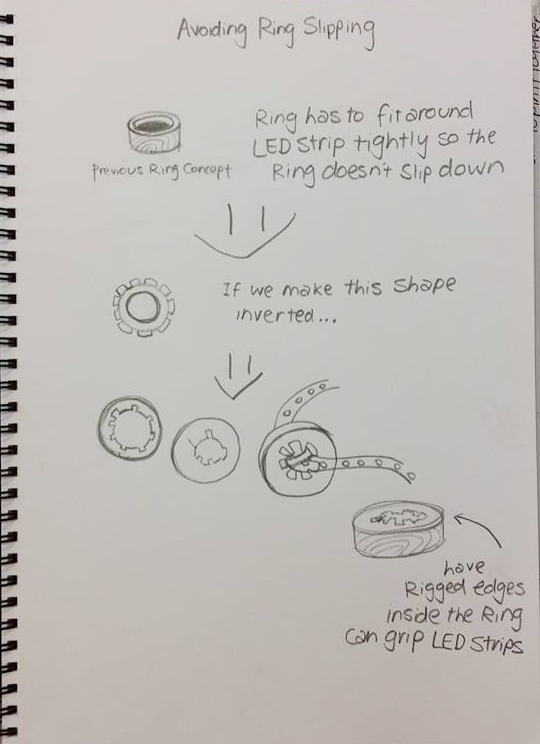

At the moment because of how the joint is made up into cross shapes we can’t extend the bulb onto the second & third cylinder.

For our first solution we thought that if we leave a gap in the middle of the joint we could actually get LED tube to sit in the middle but we did not wanted to use glue too much or either make it complicated because while they install the lamp they might snap the joint if there are too much processes involved.

At the moment because of how the joint is made up into cross shapes we can’t extend the bulb onto the second & third cylinder.

For our first solution we thought that if we leave a gap in the middle of the joint we could actually get LED tube to sit in the middle but we did not wanted to use glue too much or either make it complicated because while they install the lamp they might snap the joint if there are too much processes involved.

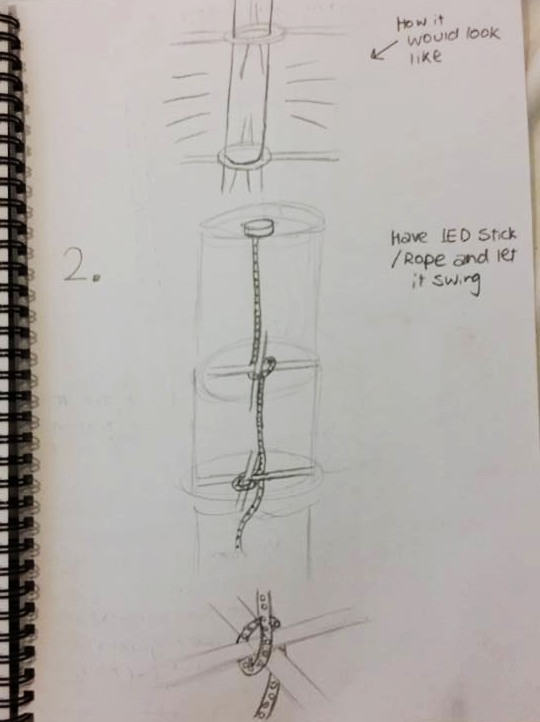

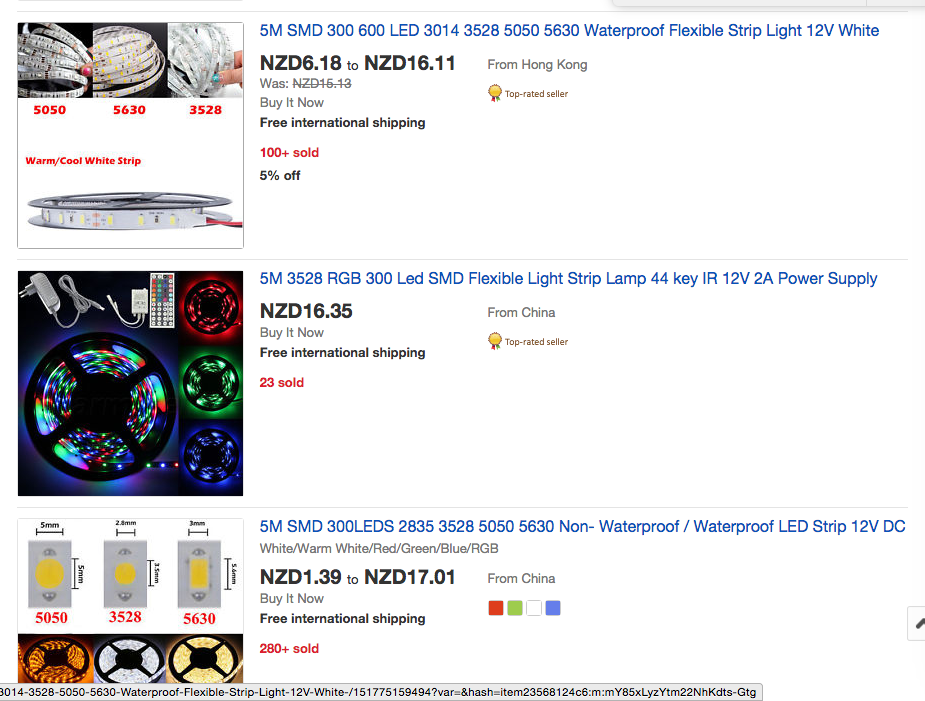

so thinking about that issue we wanted flexible LED strip or LED tube which would bend easily and hang inside our lamp.

so thinking about that issue we wanted flexible LED strip or LED tube which would bend easily and hang inside our lamp.

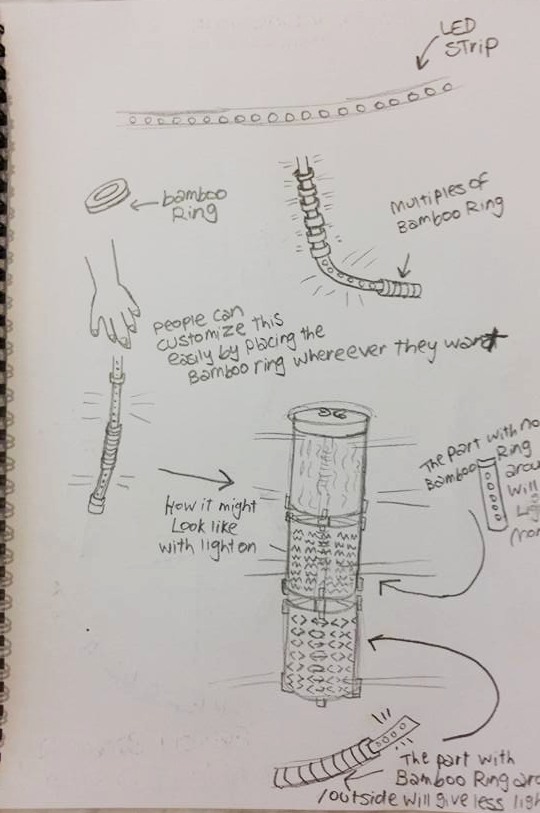

but if we make this led strips or led tube hang inside the lamp it might look ugly when you look at it from outside without the light on (in day time) so I did some research on how to decorate around the led strip.

but if we make this led strips or led tube hang inside the lamp it might look ugly when you look at it from outside without the light on (in day time) so I did some research on how to decorate around the led strip.

Obviously I didn’t want bulky decoration or non sustainable materials such as plastic tube to cover Led light I wanted to use bamboo if possible

Obviously I didn’t want bulky decoration or non sustainable materials such as plastic tube to cover Led light I wanted to use bamboo if possible

Research inspiration

Research inspiration

so basically if we laser cut multiples of bamboo ring with a rigged edges(inverted) we will be able to infix bamboo ring around LED strip and people could customize this light by simply pulling it upward or downward in their preference. This way if we even the bamboo rings around LED strip people wouldn’t be able to see ugly LED strip through our pattern holes but just see multiples of bamboo in a pipe shape.

so basically if we laser cut multiples of bamboo ring with a rigged edges(inverted) we will be able to infix bamboo ring around LED strip and people could customize this light by simply pulling it upward or downward in their preference. This way if we even the bamboo rings around LED strip people wouldn’t be able to see ugly LED strip through our pattern holes but just see multiples of bamboo in a pipe shape. Finally this is the first attempt to cut bamboo sheet in real lamp size.

All the settings are right so everything has cut through well.

Finally this is the first attempt to cut bamboo sheet in real lamp size.

All the settings are right so everything has cut through well. Here is our prototype, our joints are working well and connecting edges with pins are fine as well

Here is our prototype, our joints are working well and connecting edges with pins are fine as well

the only problem I think is that if you see the shape of cylinder it isn’t actually round as we want it to be. The resolution for this is to not cut the pattern until the edge so that it doesn’t change the roundness of the cylinder. (changing the layout of the pattern might solve this problem)

the only problem I think is that if you see the shape of cylinder it isn’t actually round as we want it to be. The resolution for this is to not cut the pattern until the edge so that it doesn’t change the roundness of the cylinder. (changing the layout of the pattern might solve this problem)

Though our pattern bends quite well regarding that it is a wood.

Though our pattern bends quite well regarding that it is a wood. so this is what I have made out of Poly. It bends really well therefore I had no problem connecting both edges together

so this is what I have made out of Poly. It bends really well therefore I had no problem connecting both edges together

Even so I couldn’t test the joint parts well (because it was too weak to hold cylinders together)

Even so I couldn’t test the joint parts well (because it was too weak to hold cylinders together) Here is the original illustration file from Kate

Here is the original illustration file from Kate

and here are the blanc file that I have made to reduce down the laser cutting time.

and here are the blanc file that I have made to reduce down the laser cutting time. The laser cutting of the corrugated cardboard was ok there were no charcoal marks and the cuts were clean.

The laser cutting of the corrugated cardboard was ok there were no charcoal marks and the cuts were clean.

We didn’t have other cardboard to use so we used corrugated cardboard

We didn’t have other cardboard to use so we used corrugated cardboard but the problem was that this material folded badly and made edges instead of bending nicely into cylinder shape

but the problem was that this material folded badly and made edges instead of bending nicely into cylinder shape

We are cutting a poly on the lasercutter but we had many issues on this material as well because when laser cut out the shape it stuck together right away.

We have increased the power on the setting manualy and it is giving us a cut but I don’t think it will be clean as we have cut cardboards. We are planning to cut our bamboo sheet when all the sized are right because we know that the Kerfpattern is working on our material.

We are cutting a poly on the lasercutter but we had many issues on this material as well because when laser cut out the shape it stuck together right away.

We have increased the power on the setting manualy and it is giving us a cut but I don’t think it will be clean as we have cut cardboards. We are planning to cut our bamboo sheet when all the sized are right because we know that the Kerfpattern is working on our material. We want sensors which will detect our movement from 4cm~3m far therefore we have found this sensor URM37 V3.2 Ultrasonic sensor.

We want sensors which will detect our movement from 4cm~3m far therefore we have found this sensor URM37 V3.2 Ultrasonic sensor. It is currently out of stock at the moment so we would have to find similar sensor around Wellington but this kind of sensors are what we want to get.

It is currently out of stock at the moment so we would have to find similar sensor around Wellington but this kind of sensors are what we want to get.

This would be about 3m far, our group figured out the measurement by the measuring tape.

This would be about 3m far, our group figured out the measurement by the measuring tape.