15 Feb 2016

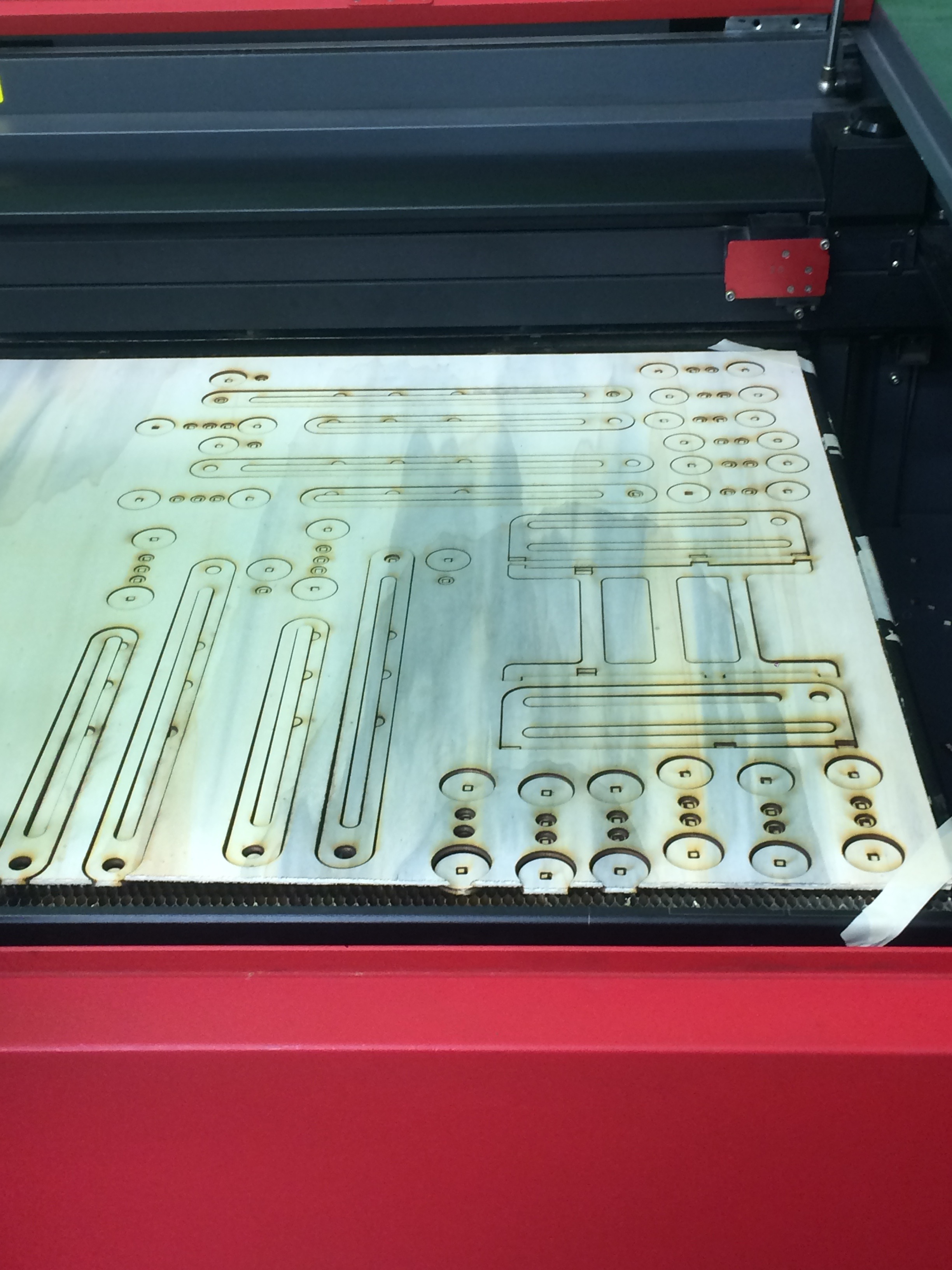

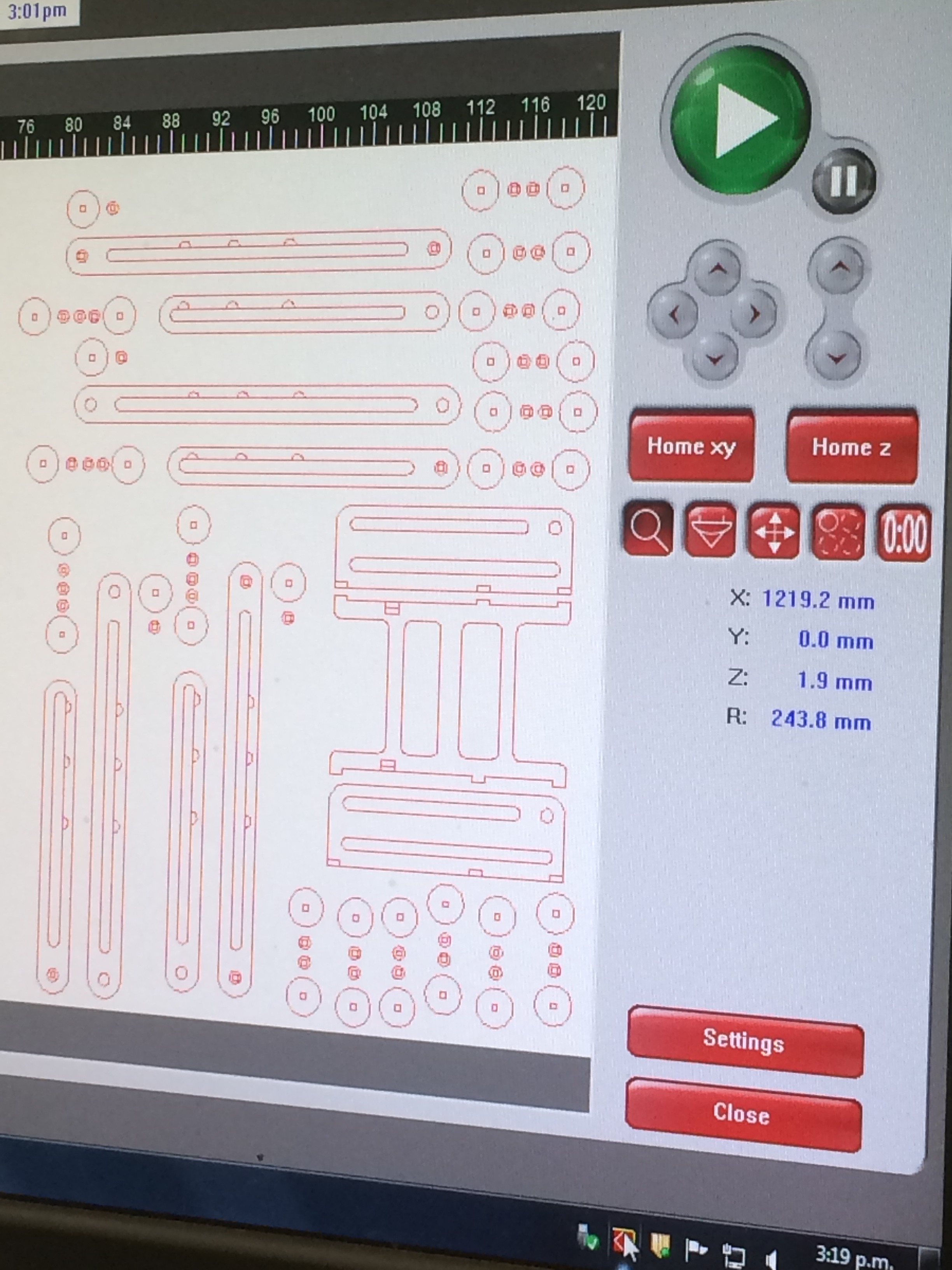

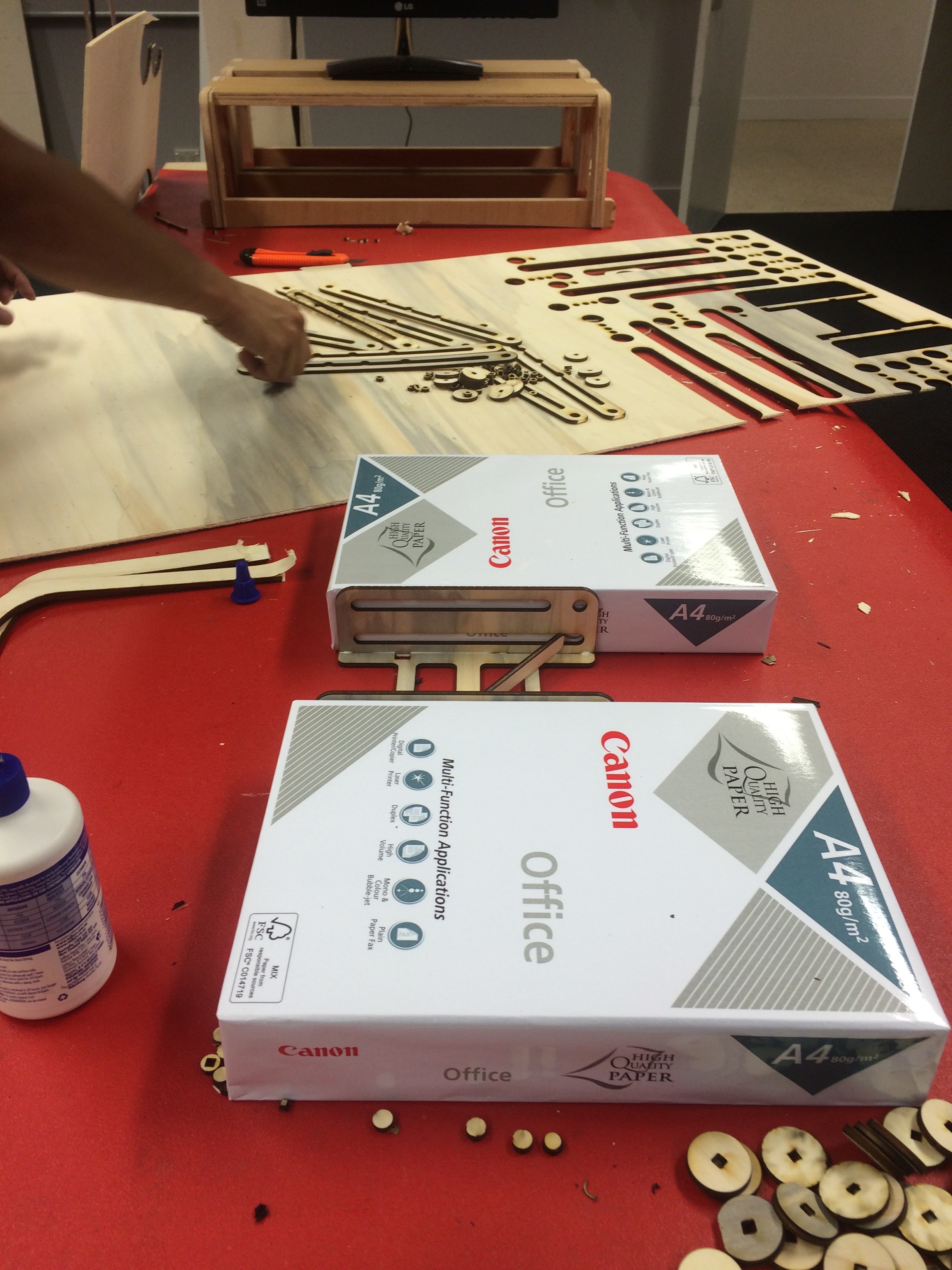

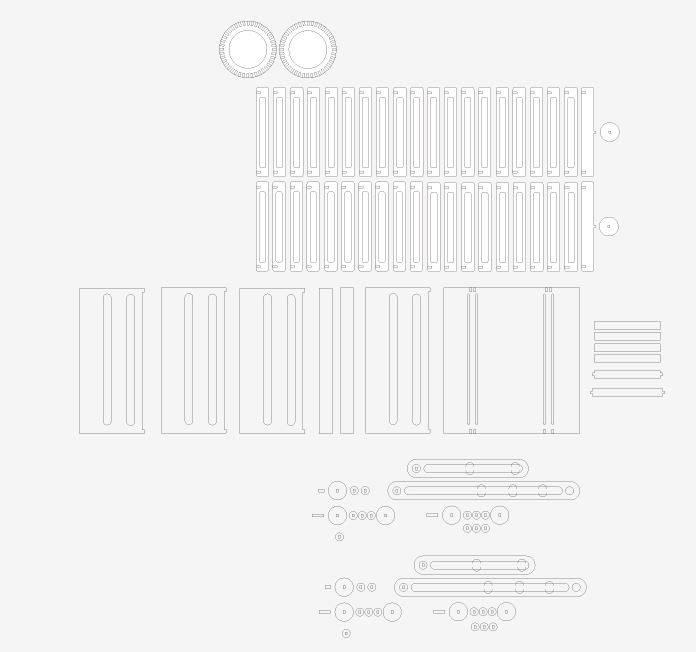

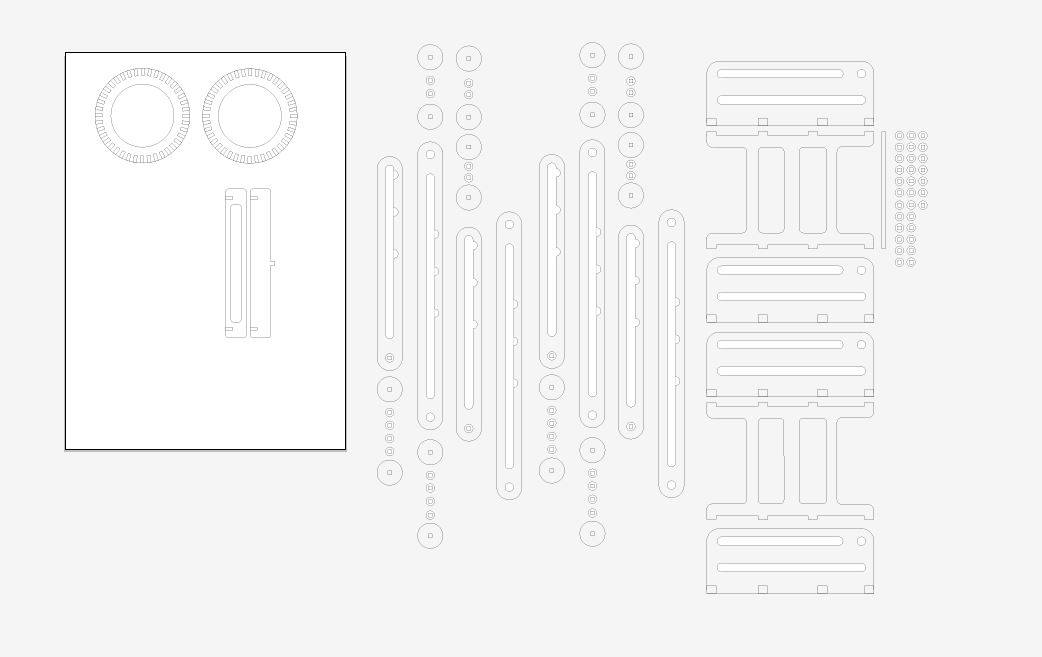

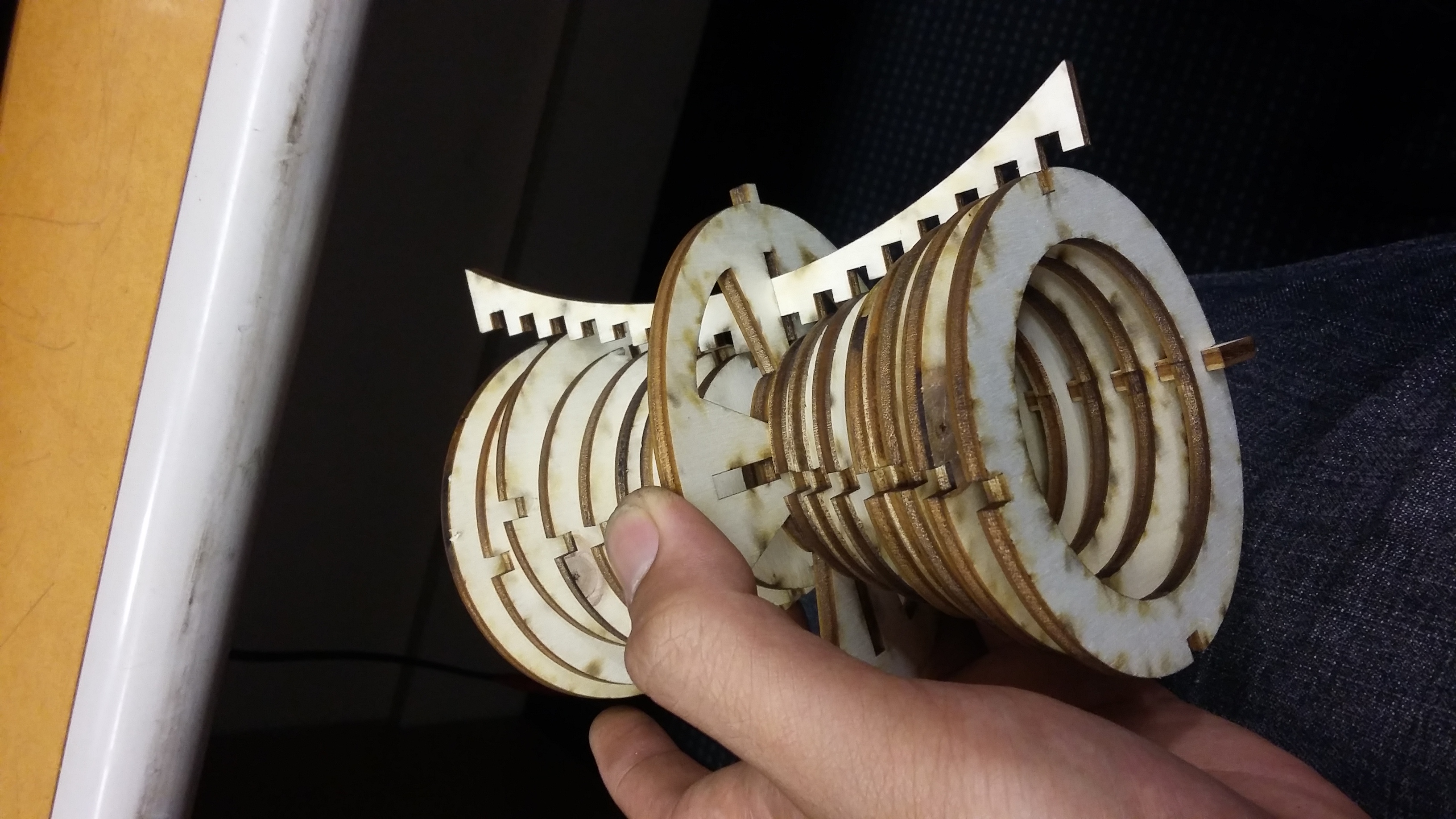

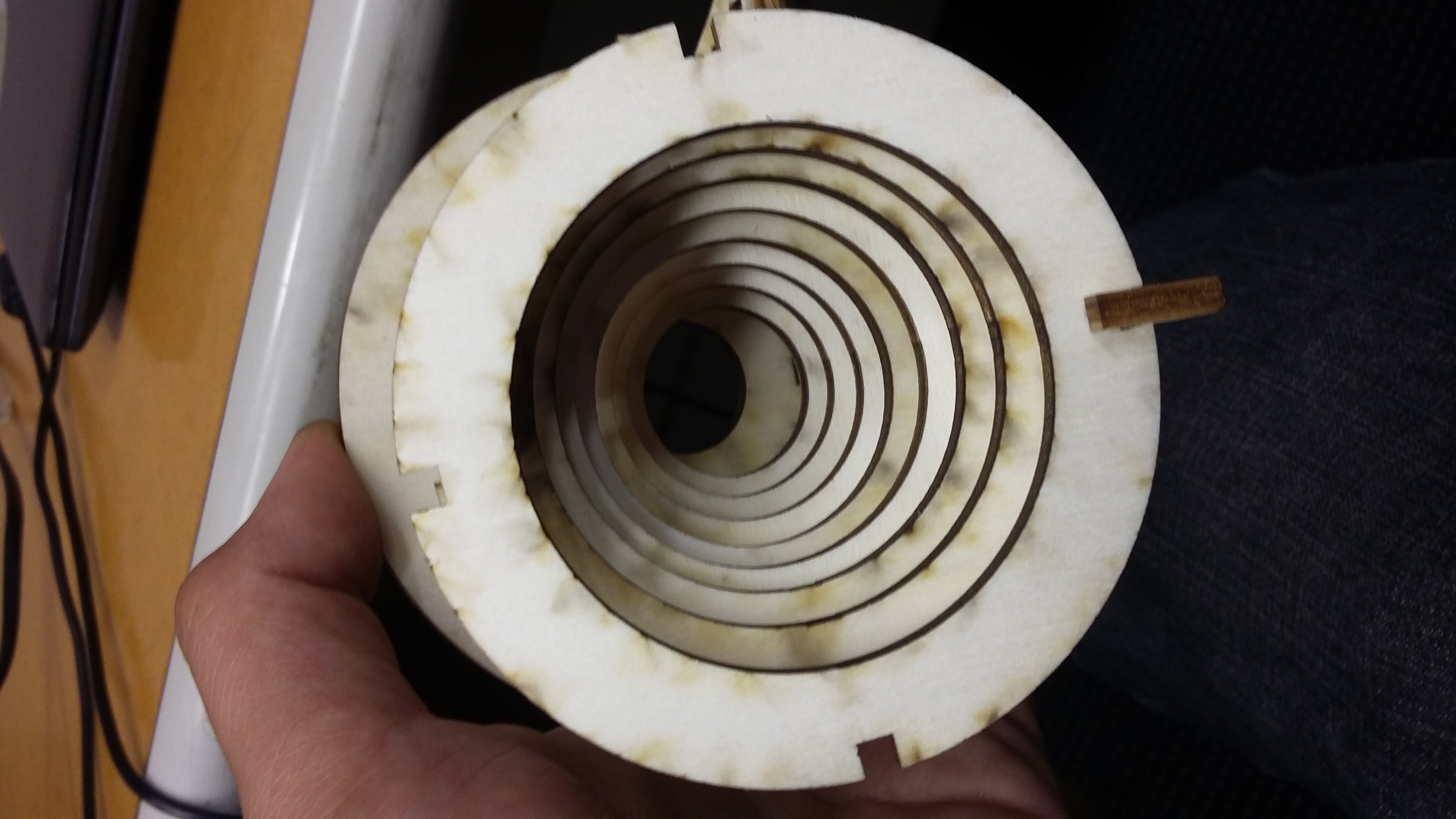

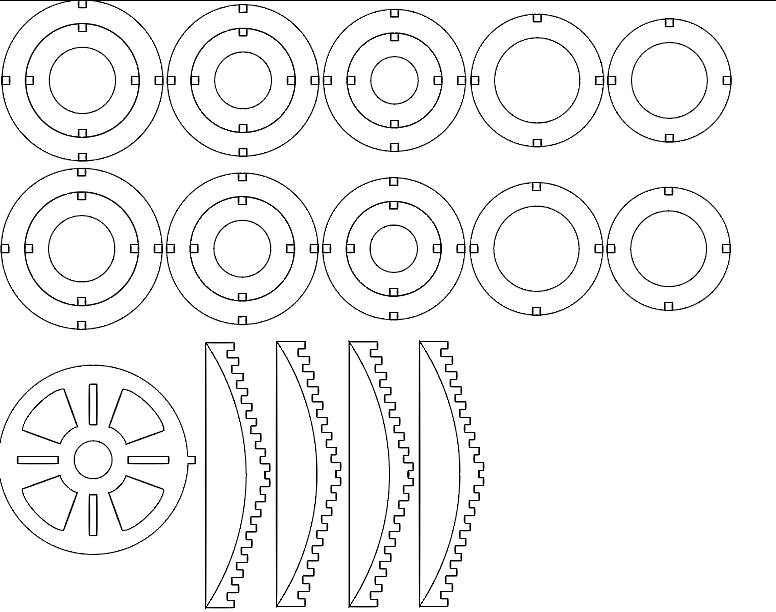

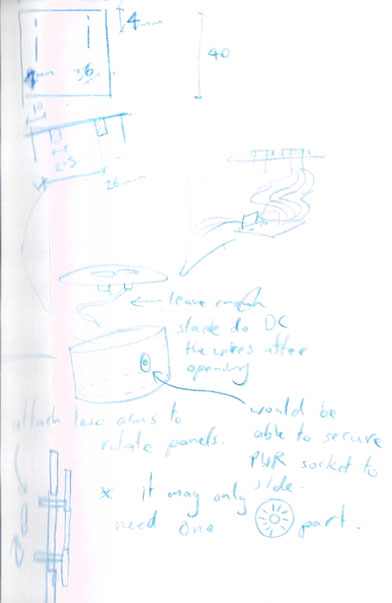

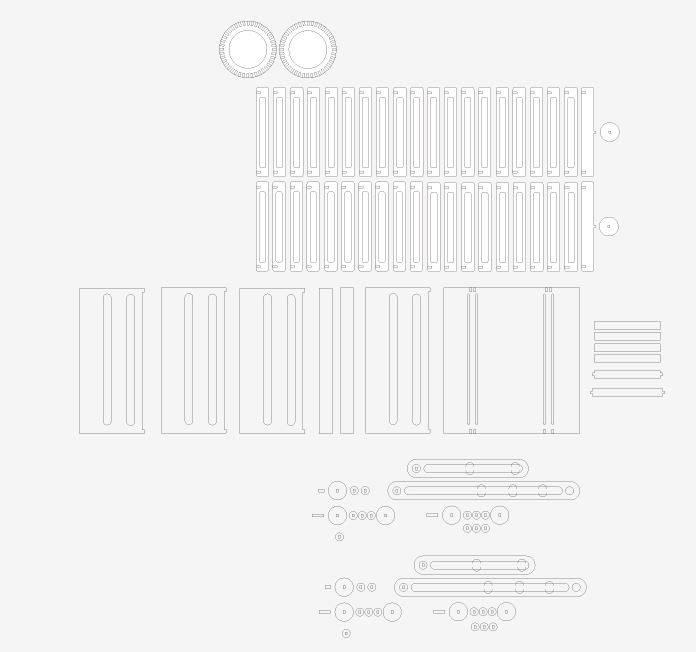

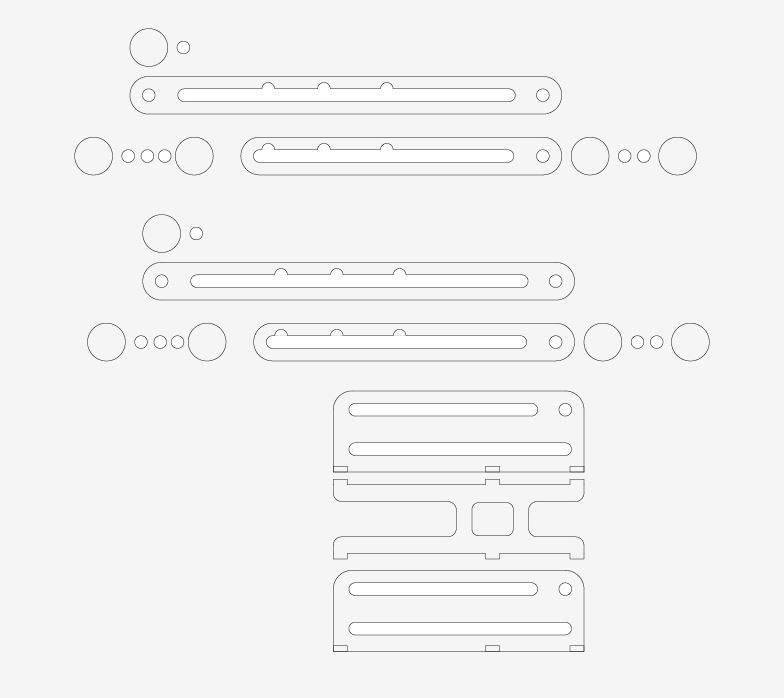

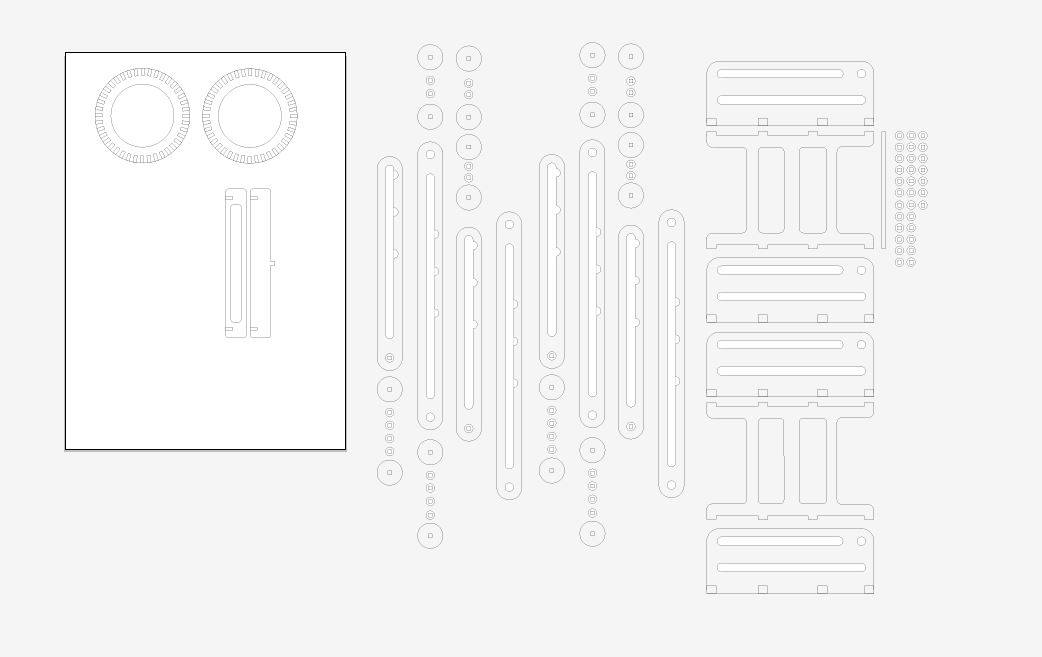

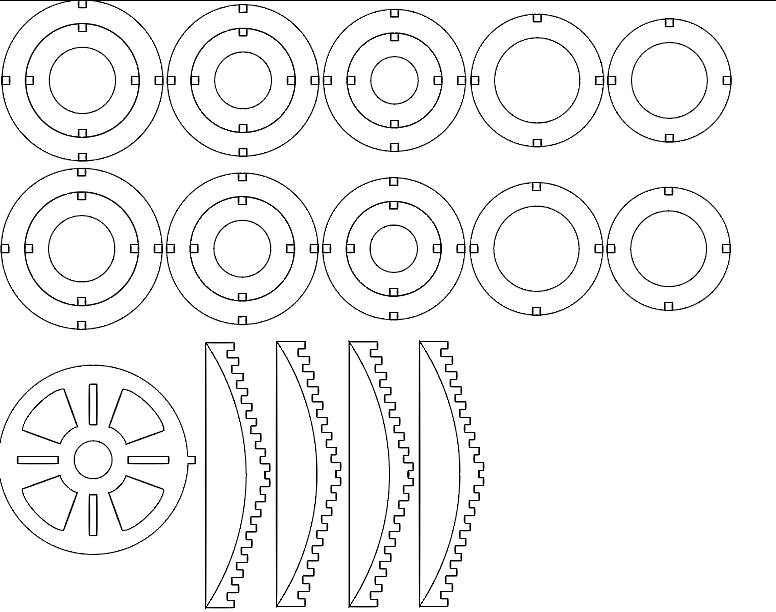

The files developed for trialing our lamp to be cut on the lazer cutter

material-ply=4mm

-Changes to the scale,and pieces needed to make the structure

-Extra parts made in file incasewe have worked out how it fits together. Also needed to make parts more stonger and supportive

-Working with similar shapes to keep simplistic.

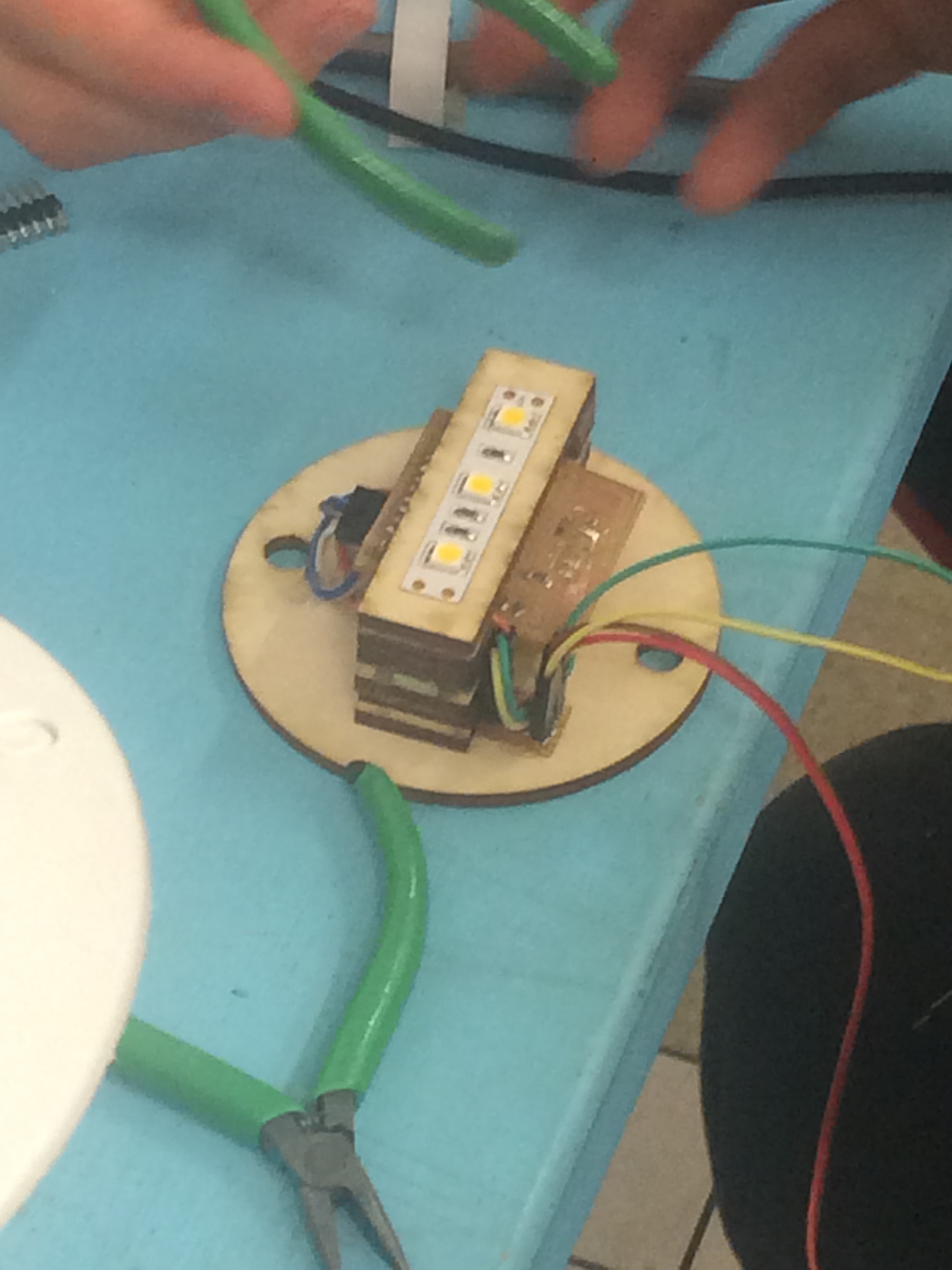

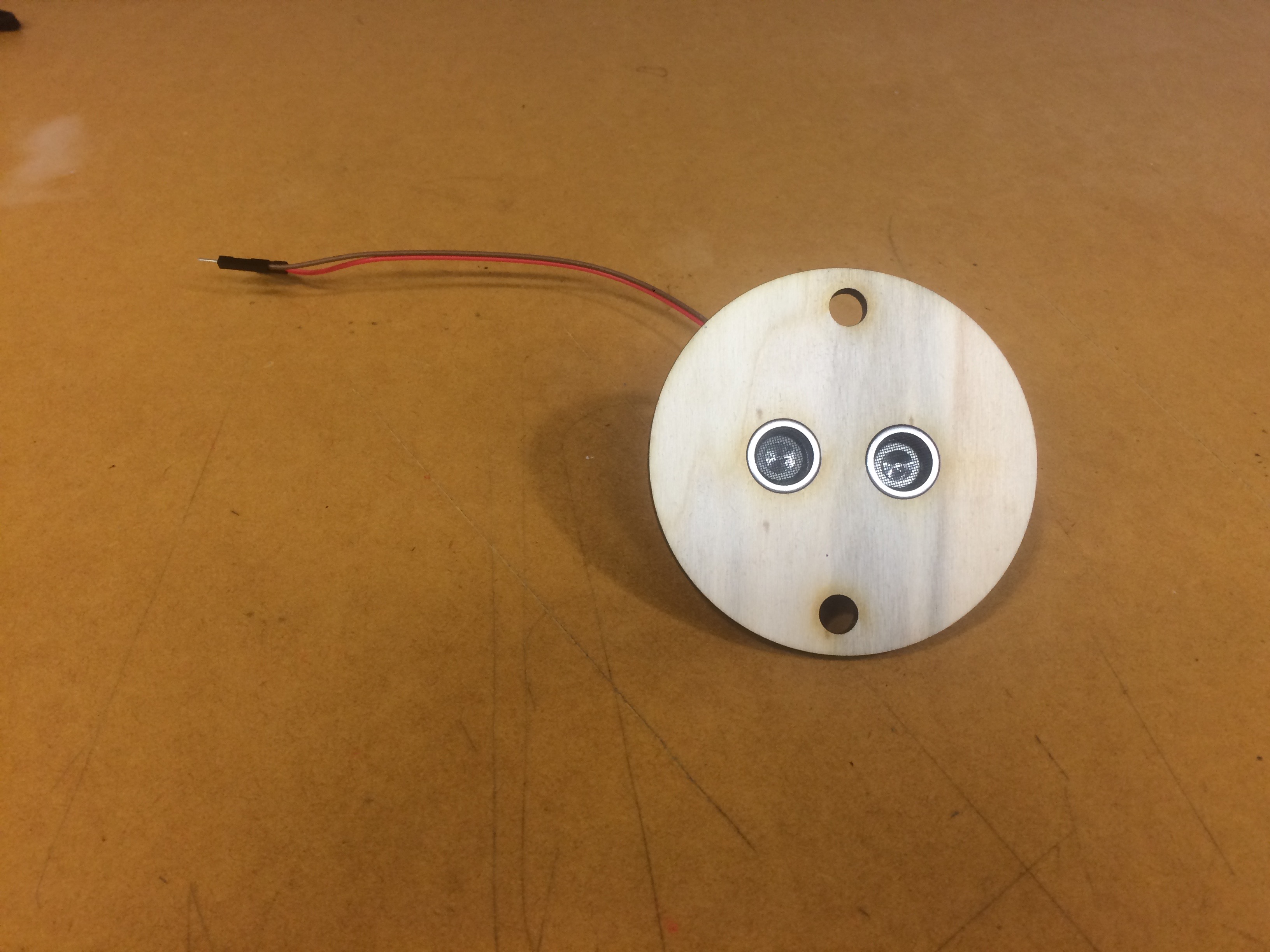

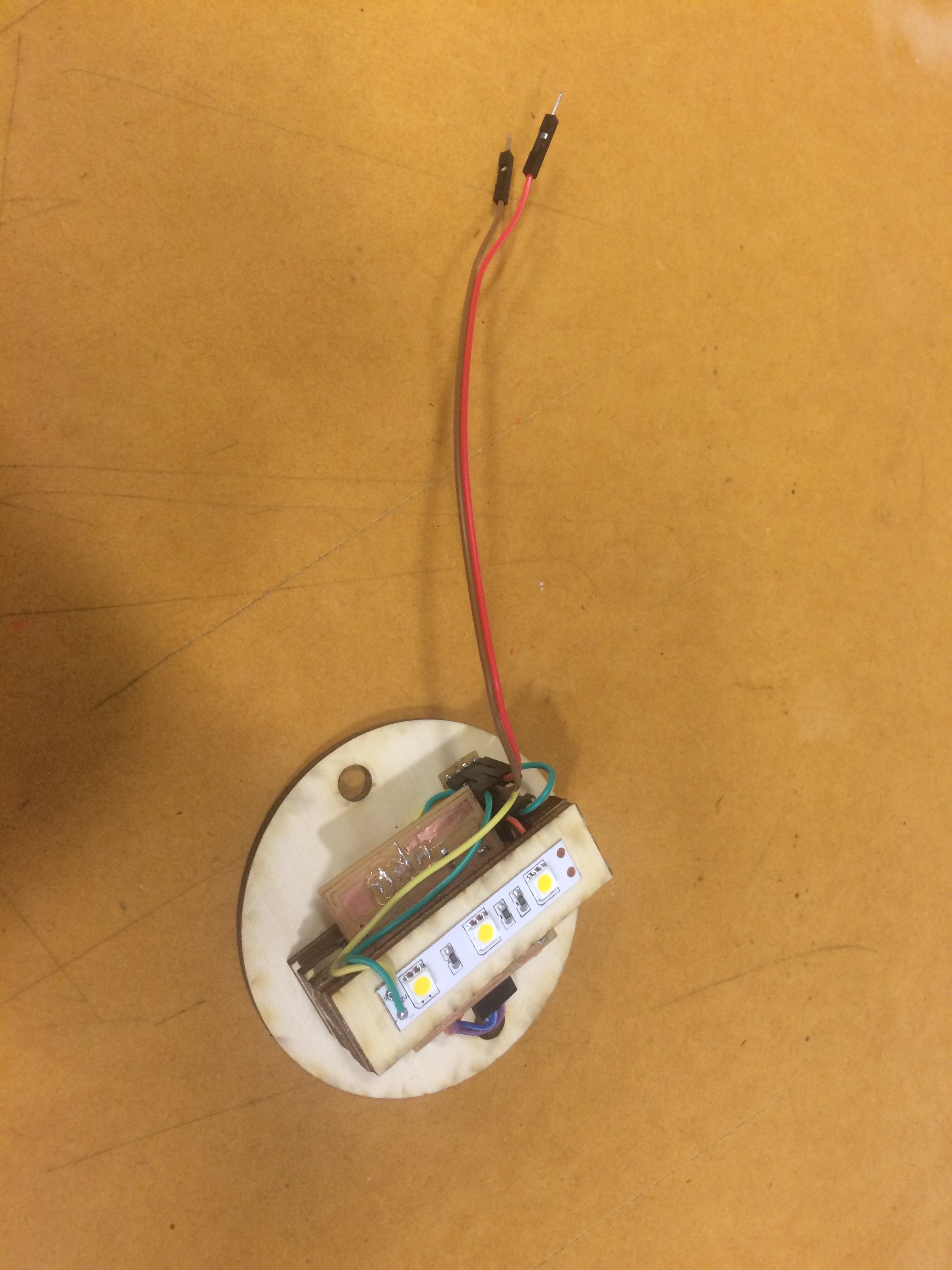

-Not the final file for the lamp base, only slight changes to be made from this to make more durable and accessable for the electronics to working with the inside of the sturcture.

-Engraved branding withing the file on separate parts of the lamp.

14 Feb 2016

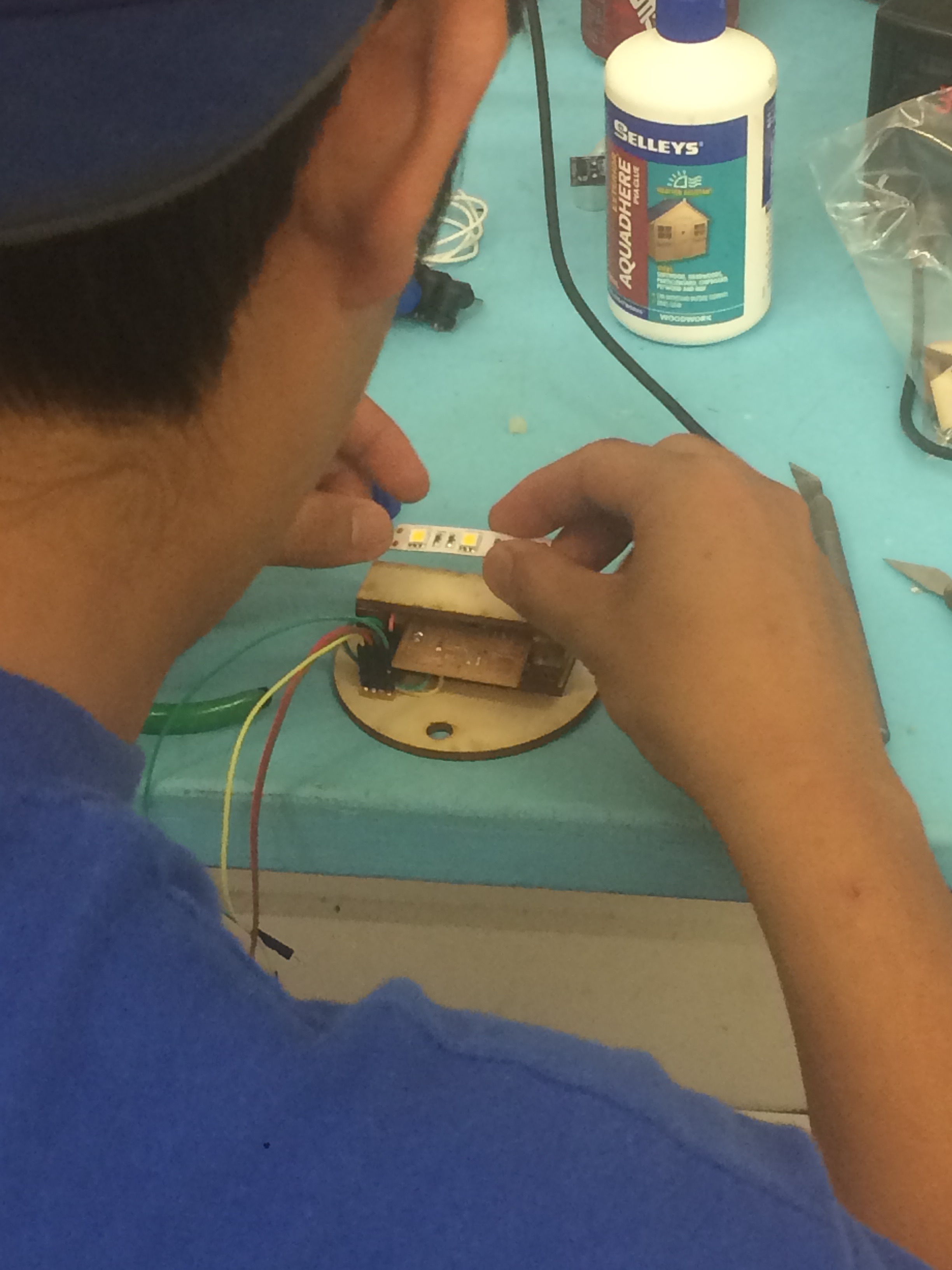

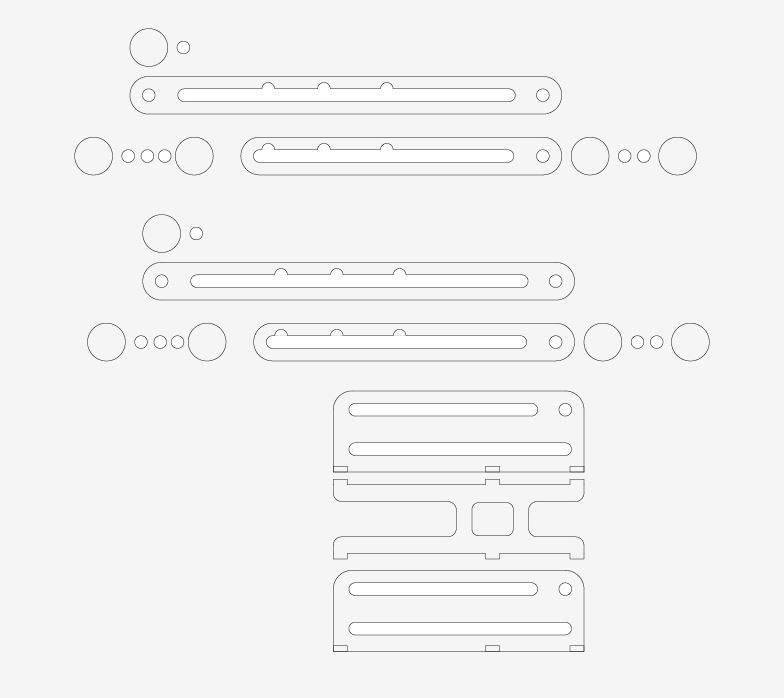

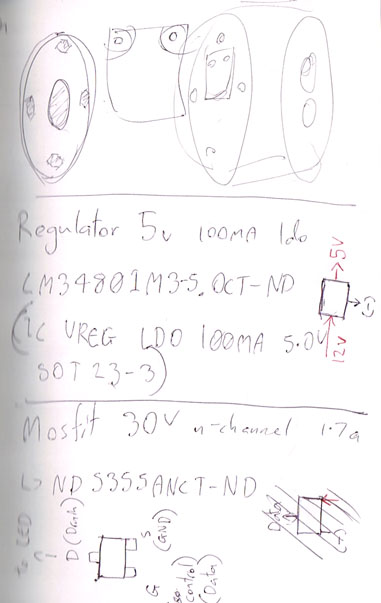

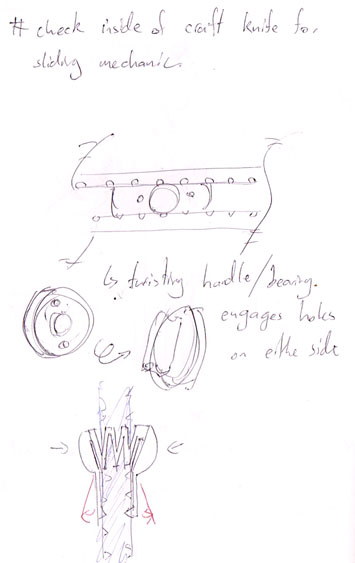

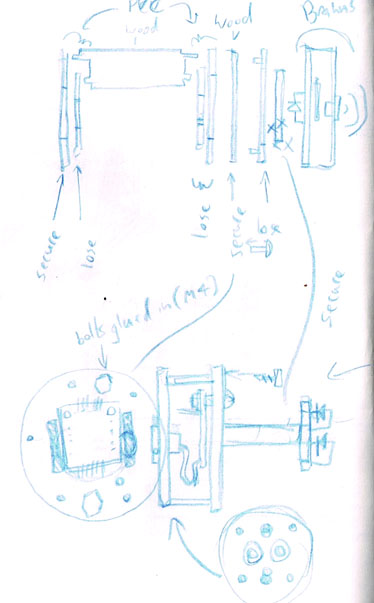

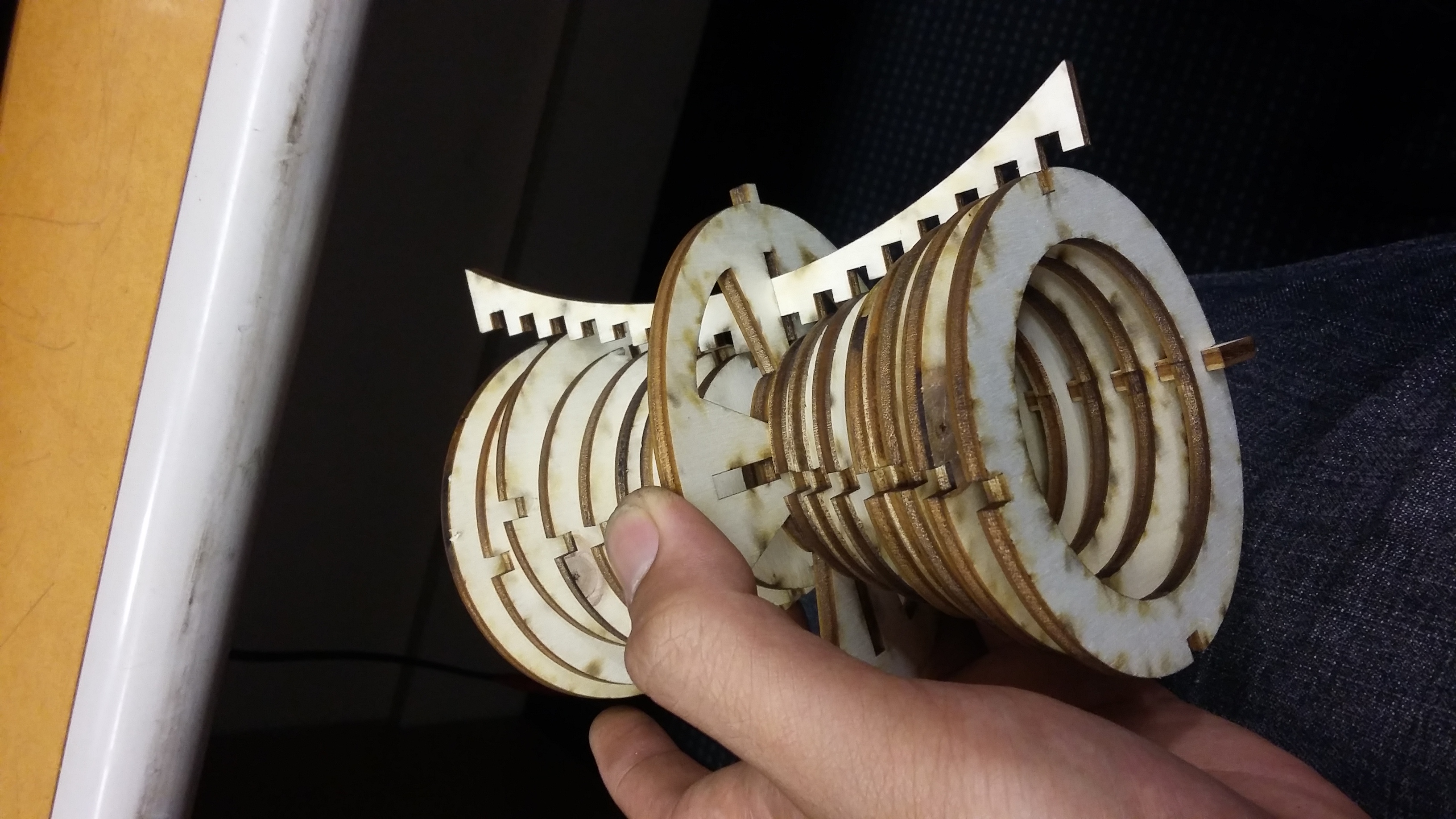

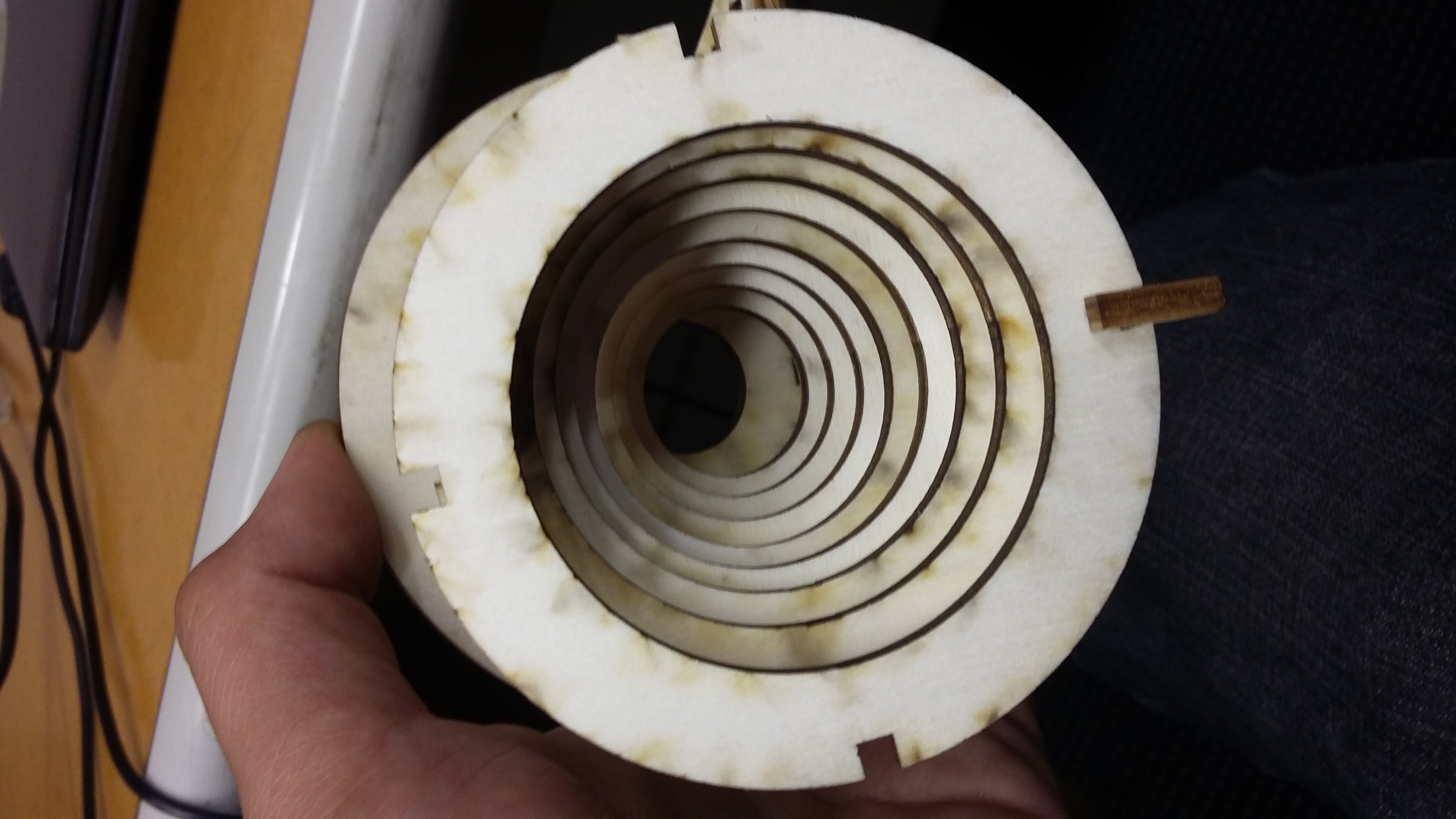

- Thought up a different lamp shade idea, so that the lamp shades can be changed. This ideally will be suitable to customise

Illustrator file testing lamp head concept.

14 Feb 2016

Team plan for the week

we need to set some sort of to do list to make sure we have a presentation and working lamp by the hand in on friday

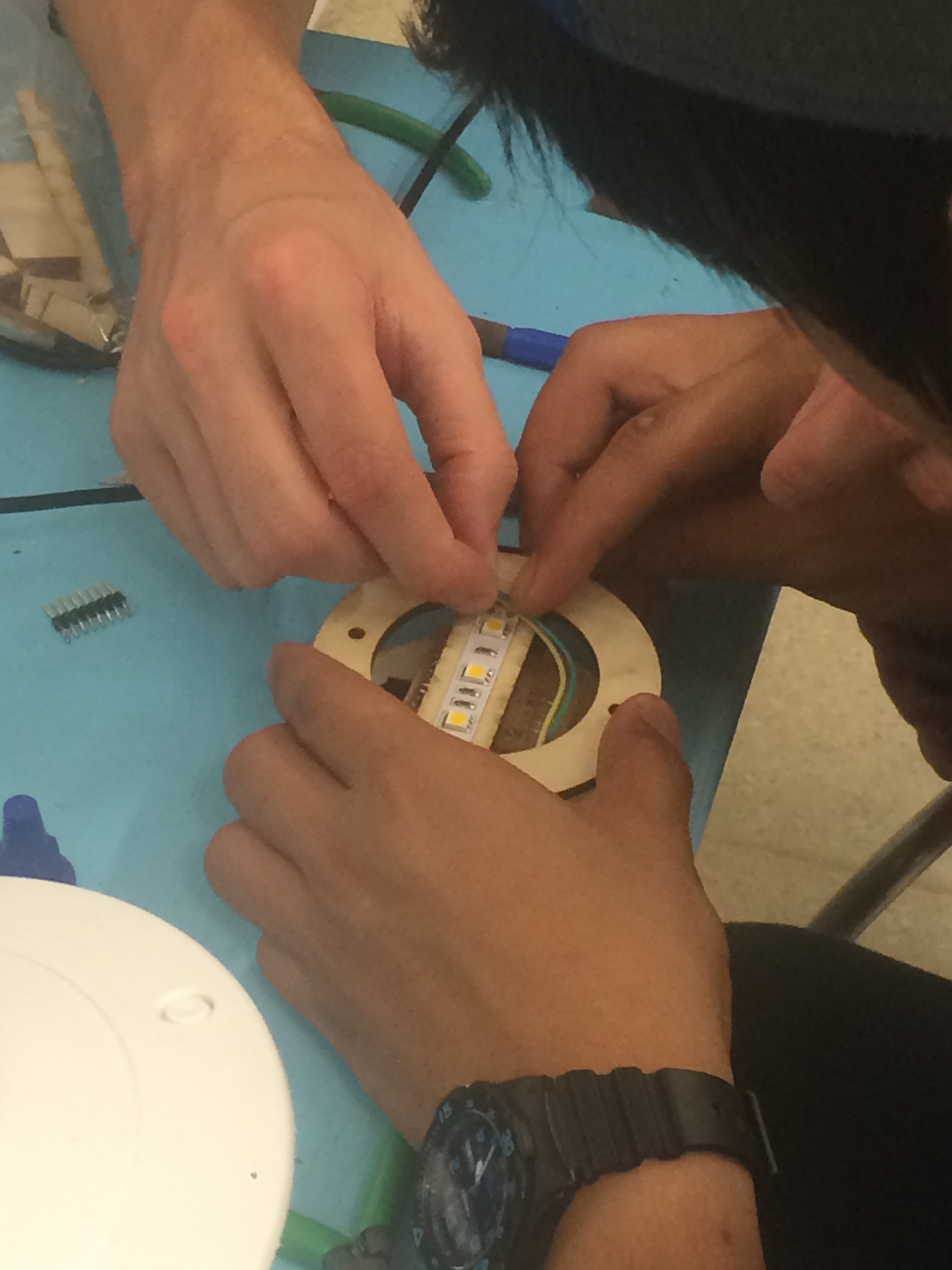

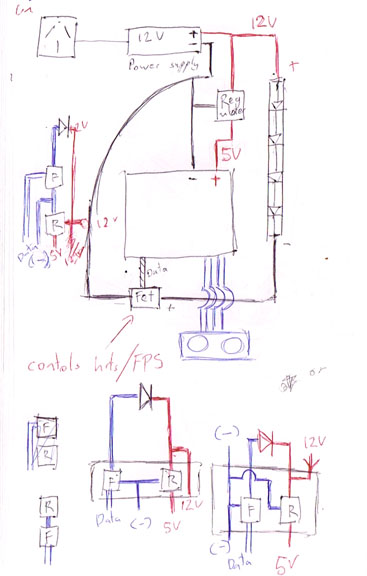

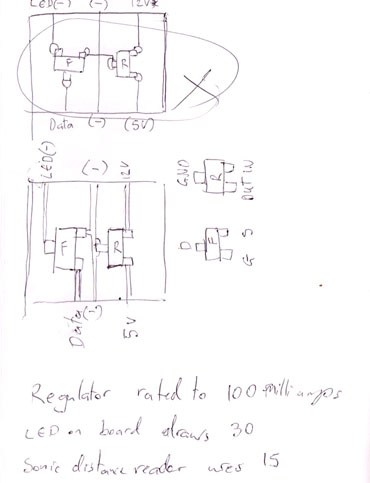

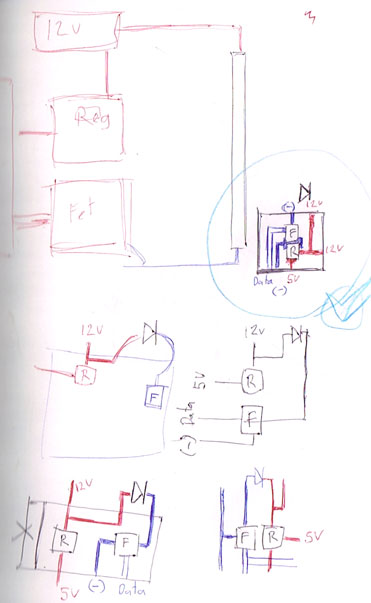

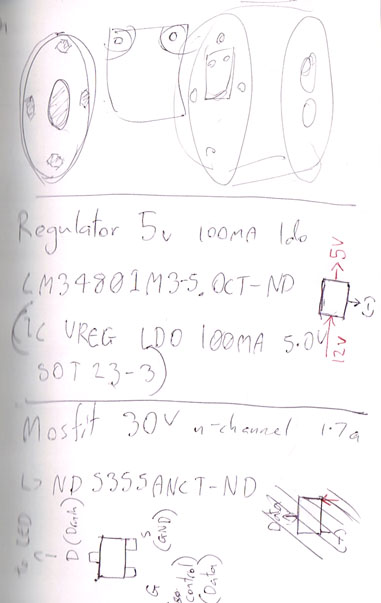

-Working electronics for the light

-Final design of lamp

-Material sorced and lasercutter booked

-logo designed for lamp

-Instructions and files for lamp

-Updated blog with all componentsof work we have done

-Presentation

Also a key thing will be : being in the FabLab out of class times. Keeping group members in the know of what changes and development has been happening, so work can continue to flow